14

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When diag-

nosing faults in operation of the wrench, always check that the hydraulic power source is supplying the correct hydraulic

fl ow and pressure to the tool as listed in the following table. Use a fl ow meter known to be accurate. Check the fl ow with

the hydraulic fl uid temperature at least 80

o

F/27

o

C.

PROBLEM

CAUSE

SOLUTION

Tool will not start.

Power not being supplied.

Check to make certain that both hoses

are connected.

Turn hydraulic circuit control valve ON.

Defective quick disconnects.

Check each quick disconnect.

Low drilling torque.

Relief valve set too low.

Set relief valve at 2100 psi/145 bar.

Fluid restriction in hose or valve.

Excess fl ow and pressure loss.

Locate and remove restriction.

Use correct fl uid.

Fluid not warmed up. Prehead system.

Hoses too long for hose ID. Use

shorter hose.

Hose ID too small for hose length. Use

larger ID hose.

Low tool speed.

Fluid fl ow rate is too low.

Check circuit fl ow rate.

High tool speed.

Fluid fl ow rate is excessive.

Check circuit fl ow rate. Add proper

fl ow control valve or reduce the pump

RPM.

Oil leaks around gear housing.

Hydraulic pressure and return hoses

reversed.

Correct hose connections. Pressure

should be to the handle port away

from the trigger, return is near the

trigger, then replace the main shaft oil

seal.

Oil gets hot, power unit working hard.

Open-center tool on a closed-center

circuit or vice-versa.

Use tools to match circuit.

Circuit relief set too low.

Adjust relief valve to 2100 psi/145 bar.

Too much oil going through tool.

Adjust fl ow for 12 gpm/45 lpm maxi-

mum or less.

Oil leaks at reversing spool.

Damaged O-Rings.

Replace as required.

Wrong hydraulic fl uid. Circuit too hot.

Refer to Operation Instructions for cor-

rect fl uid/circuit specifi cations.

Oil leak at motor cap face.

Fasteners loose.

Refer to Service Instructions

Face O-Ring worn or missing.

Replace as required.

Motor cap/main housing damaged.

Replace as required.

Summary of Contents for DL07

Page 2: ......

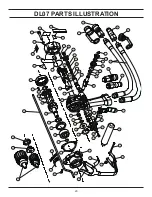

Page 20: ...20 DL07 PARTS ILLUSTRATION ...