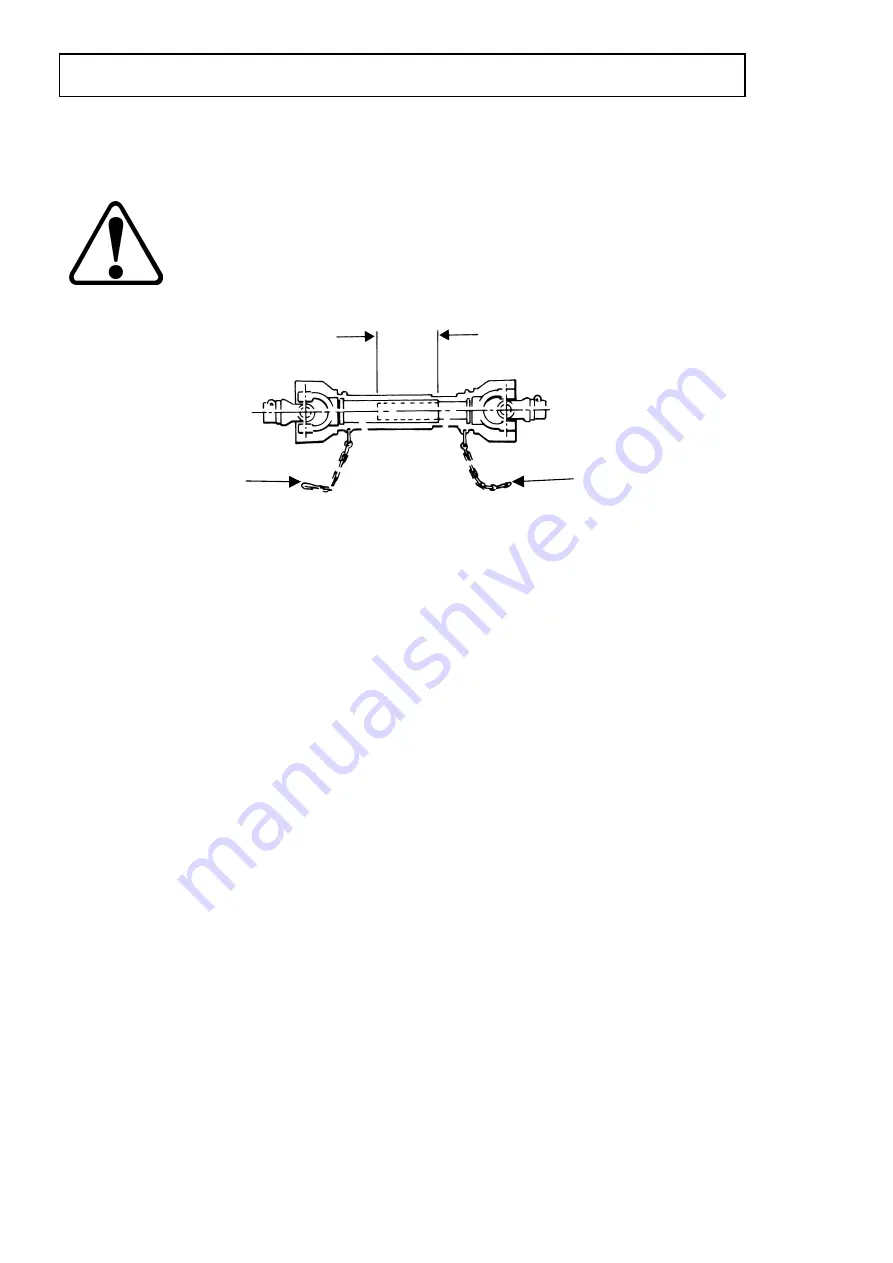

minimum1/2 overlap

PTO Shaft

The machine is designed to operate with the tractors 540 rpm, 6 spline, 1 3/8” PTO

output shaft.

PTO speeds greater than 540 rpm will cause damage to the system

and if exceeded may invalidate the warranty.

Fit the two halves of the PTO shaft onto their respective drive shafts on the machine

and tractor. Check the shaft length by turning the tractor fully in both directions with

the machine in its working position while attached to the tractor’s pick-up hitch.

Ensure the sliding tubes, when fully extended, have an overlap at least half the

closed length (see figure 3). Ensure that the ends of the sliding tubes when at the

shortest point are not in contact with other parts of the PTO shaft. If necessary,

shorten both tubes and guards equally to achieve end clearance at the minimum

length position.

Make sure that the drive shaft is fitted correctly and that the lock pins are engaged.

All the parts of the PTO shaft, especially the guards, must be kept in good order.

Check regularly that the guard is undamaged and fully protects the whole of the

shaft, and that both the guard and the shaft will telescope freely.

If it is possible to engage the inner and outer parts of a drive in more than two

positions circumferentially then make sure that the universal joint yokes are correctly

aligned.

Check that when in the continuous working position, the drive shaft is not at an angle

of more than 20° from the PTO centre line. The angle between the drive shaft and

the input and output shafts should be equal.

Ensure that the safety chains (item 1, fig 3) used to prevent the guards from turning,

are fixed to the tractor and implement in such a way that they will not be stretched

when the drive shaft is at maximum articulation. When disconnected from the tractor,

position the PTO shaft on the drawbar PTO rest as shown in figure 1.

1.9

INSTALLATION

1

1

Fig 3

Summary of Contents for Unistar 2400

Page 2: ......

Page 4: ......

Page 10: ...1 5 SAFETY PRECAUTIONS ...

Page 11: ...SAFETY PRECAUTIONS 1 6 ...