17

6.3- Assembling the Pump

6.3.1- Getting Prepared for Mounting

• It must be ensured that the parts to be used are clean before starting mounting. Clean the oil, dirt

on the parts with a solvent.

• The impeller and the body must be inspected for wear, fraction and breakdown.

• Replacement is necessary if the radial clearances between the impeller and the volute casing

1 mm.

• It must be ensured that the surfaces of the O-ring and/or bolts are clean.

6.3.2- Mounting

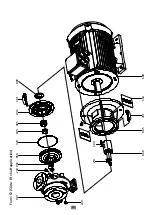

The mounting procedure is the reverse of the demounting procedure. Exploded view or cross sectional

view can be referenced during mounting.

• Put the shaft (060) on the electric motor (600). Don’t tighten the set screw (380) completely.

• If rigid coupling is used, put the rigid coupling (085) on the electric motor (600) shaft.

• In sequence, put allien screw and washer (340), shaft (060) with screws (320).

• Put the thrower (088) on the shaft.

• Assemble the motor pedestal (005) on the electric motor (600).

• Put the mechanical seal cover (043) on the motor pedestal (005).

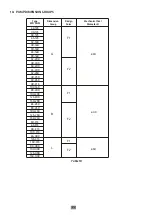

• According to pump group, arrange S value

(see table 5)

tighten the set screw (380) completely on

the shaft.

• First put the stationary part of mechanical seal (405) and after that put the rotationary part.

• Put the mechanical seal spacer sleeve (049) on the shaft (060).

• Attach the impeller key (210).

• Insert the impeller (050) and tighten the impeller nut (065).

Be careful with processed surfaces. The defects on the processed surfaces may cause

permanent damages.

ATTENTION

S

Figure 9.

Mounting the pump shaft on the electric motor shaft