9

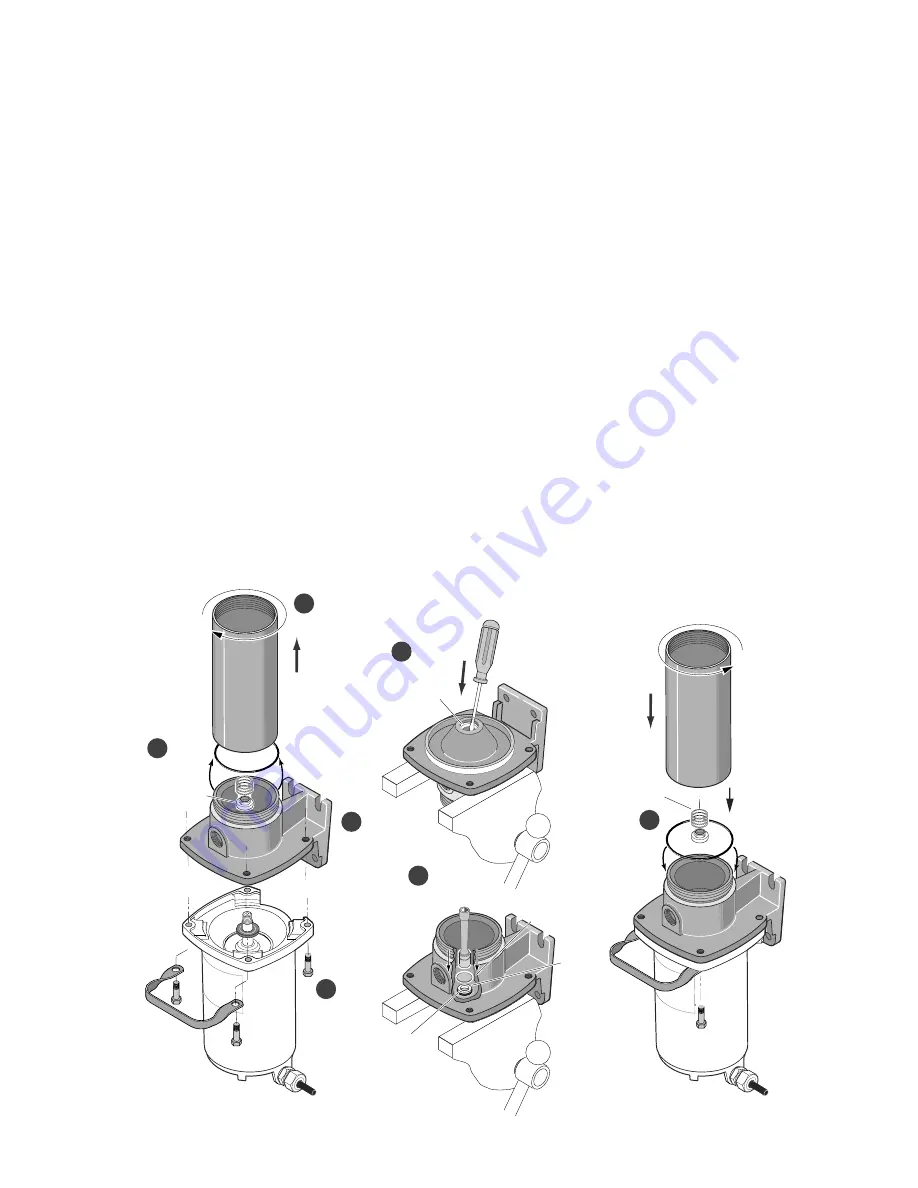

Mechanical Seal Changeout

(refer to Figures 7 and 8)

This procedure is best completed with the pump held in

a vertical position, motor down.

First complete

“Disassembly”

instructions 1 through 5

under

“Impeller Stack Changeout.”

(see Figure 7).

6. Remove 4 capscrews holding pump body to motor.

Pump handle will come off with top capscrews.

7. Unscrew pump shell from pump body, turning

clockwise (left hand threads).

8. Remove mechanical shaft seal spring and rotating

half from motor shaft. Use care not to scratch motor

shaft when removing rotating half.

9. Remove pump body from motor and place on flat

surface, face down. Again, use care not to scratch

motor shaft.

10. Use a screwdriver to push ceramic seat out from

seal cavity as shown.

11. Installation of ceramic seat:

A. Turn pump body over so seal cavity is up; clean

cavity thoroughly.

B. Clean polished surface of ceramic seat with a

clean cloth.

C. Lubricate outside rubber surface of seat with

soapy water. Place cardboard washer over

polished face of seat and press into seal cavity

using a 3/4” socket or a piece of 3/4” standard

pipe.

D. Be sure polished surface of seat is free of dirt

and has not been damaged by insertion. Re-

move excess soapy water. Dispose of card-

board washer.

12. Installation of rotating half and spring:

A. Reinstall pump body on motor using extreme

caution not to hit ceramic portion of seal on

motor shaft. Reattach pump body to motor using

capscrews. Be sure to reinstall pump handle at

this time.

B. Inspect shaft to make sure that it is clean.

C. Clean face of rotating half of seal with a clean

cloth.

D. Lubricate inside diameter of rotating half with

soapy water and slide onto motor shaft (sealing

face first).

E. Place spring over motor shaft so it rests on

rotating half.

13. To complete reassembly from this point, reverse

instructions 1 through 5 under

“Impeller Stack

Changeout.”

NOTICE:

Lubricate suction and discharge O-Rings

with soapy water for easier installation of shell.

Ceramic Seat

3/4" pipe or

3/4" socket

with extender

Polished

Face

Rotating

Half

Cardboard

washer (supplied

w/seal)

Rotating Half

of Mechanical

Seal

Remove shell;

turn clockwise.

Push ceramic

seat out of

pump body

Remove

Pump Body

6

8

7

9

10

11

12

1212 0894

Figure 8 – Mechanical seal changeout.