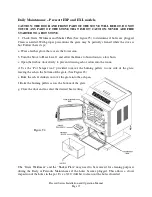

Prescott Series Installation and Operation Manual

Page 49

#

PART NUMBER

DESCRIPTION

35

80P53681-R

SLIDE-TOP STANDOFF PLATE ASSEMBLY

36

80P53785-R

CONTROL BOARD BOX W/ CLINCH STUDS

37

80P30523B-R

CONTROL BOARD

38

80P52658-R

CONTROL BOARD HARNESS RESTRAINT

39

80P30045-R

THERMOSTAT TERMINAL

40

80P20004-R

POWER CORD

41

80P20248-R

5/8” COLLAR WITH SET SCREW

42

80P54074-R

MOTOR MOUNT BRACKET AND END CAP

43

80P20245-R

AUGER GASKET

44

80P53666-R

AUGER WELDMENT

45

80P60083-R

AUGER WASHER

46

08P30191-R

MOTOR RETAINER BRACKET

47

80P20278-R

AUGER MOTOR

48

80P20003-R

CONVECTION BLOWER

49

80P31220-R

FRONT BUSHING PLATE

50

80P31221-R

REAR BUSHING PLATE

51

80P53695-R

SHAFT/CAGE WELDMENT

52

80P52953-R

VERSA GRATE BRACKET ASSEMBLY

53

80P20296-R

VERSA GRATE MOTOR

54

80P52372-R

VERSA GRATE COLLAR W/ SETSCREWS

55

80P52376-R

CAM CONNECTOR ROD

56

80P50560-R

CAM

PARTS

NOT SHOWING

N/A

80P31219-R

REMOVABLE BUSHING MOUNT PLATE

N/A

80P21403-R

WIRING HARNESS

N/A

80P52630-R

TERMINAL BLOCK

N/A

X-113HT

RUBBER HOPPER SEAL – 35”

N/A

80P54121-R

ROD TOOL ASSEMBLY

N/A

80P20057-R

250 VOLT 5 AMP FUSE