20

2 Operation

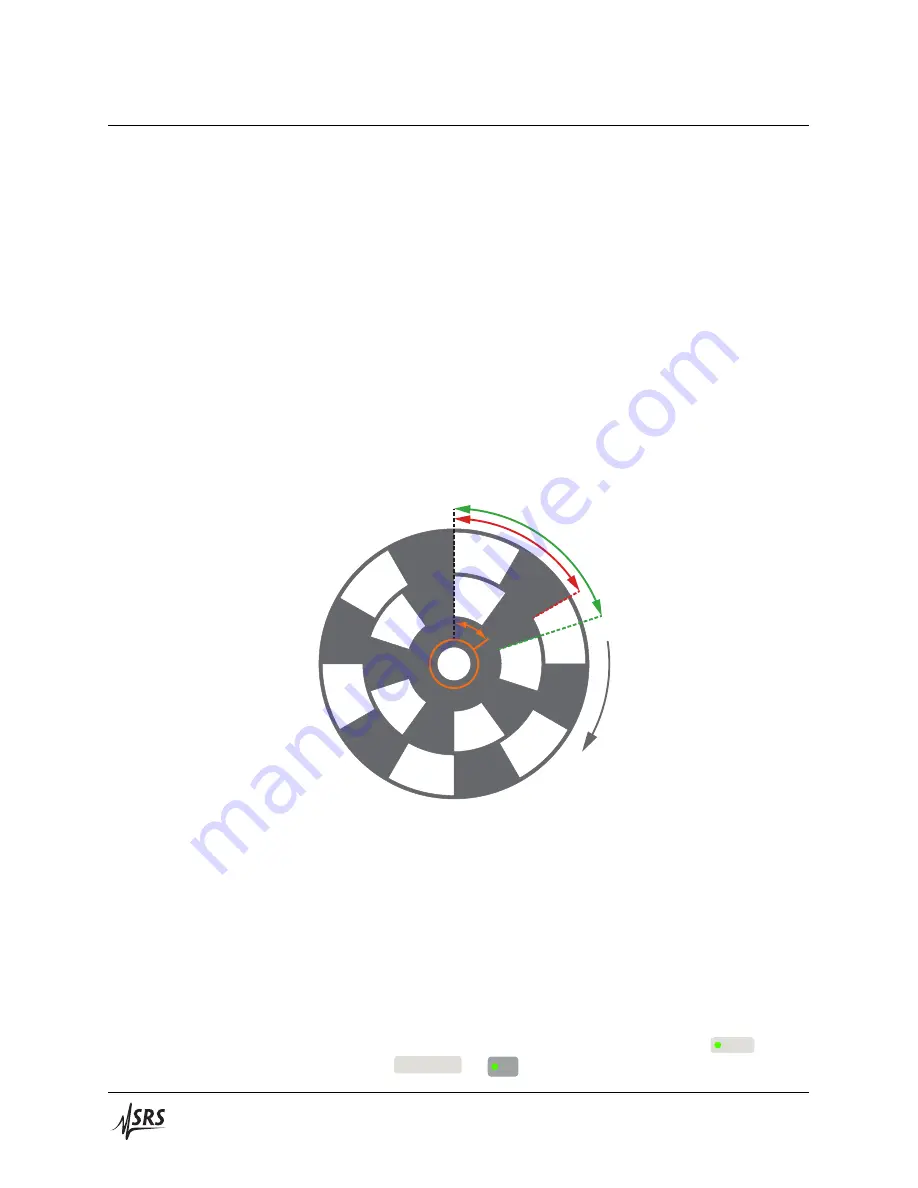

2.1.2 Chop Mode

Chop mode refers to the standard use case of an optical chopper in

which the motor runs at a steady rate in order to provide a chopped

optical signal with the appropriate frequency and phase.

It is instructive to consider in detail the meaning of phase under var‑

ious instrument configurations. For all of the following examples, we

use the O54256 5/6 slot dual‑frequency blade, with the shaft encoder in‑

dex position arbitrarily oriented at +54

°

mech relative to the coincident

inner and outer track edges, as depicted in Figure 2.2. The shaft encoder

produces a once‑per‑revolution pulse (output high), with a duration of

1/400

th

of a mechanical revolution, as the index position rotates through

the encoder’s optical sensor. The pulse is available at at

Rotor Shaft Ref

Out

.

For a chopper blade track with

𝑛

slots

, a mechanical rotation of 360

°

mech/

𝑛

slots

produces a full 360

°

opt cycle.

Outer: 360°opt

= 60°mech

Inner: 360°opt

= 72°mech

54°mech

Rotation

Figure 2.2:

Relationship between optical and mechanical degrees (

°

opt and

°

mech) for O54256 5/6 slot dual‑frequency blade. Positive rotation of the chop‑

per blade is clockwise when viewed from the front of the chopper head. The

shaft encoder index orientation (which is

not

a feature of the chopper blade

itself, and will generally vary for any given chopper head unit) is shown in

orange. For ease of comparison to the timing diagrams below, the index orien‑

tation is measured relative to the coincident edges of the inner and outer tracks

(leading by +54

°

mech in this example).

2.1.2.1

Shaft Control

First consider the instrument configuration and timing diagram of Fig‑

ure 2.3, in which the SR542 is configured to control the

Shaft

, with a

frequency

Multiplier

of

×

1

. The

Rotor Shaft Ref Out

(one‑pulse‑per‑

SR542 Precision Optical Chopper