146 System Updates

2005995 Rev O – 210712

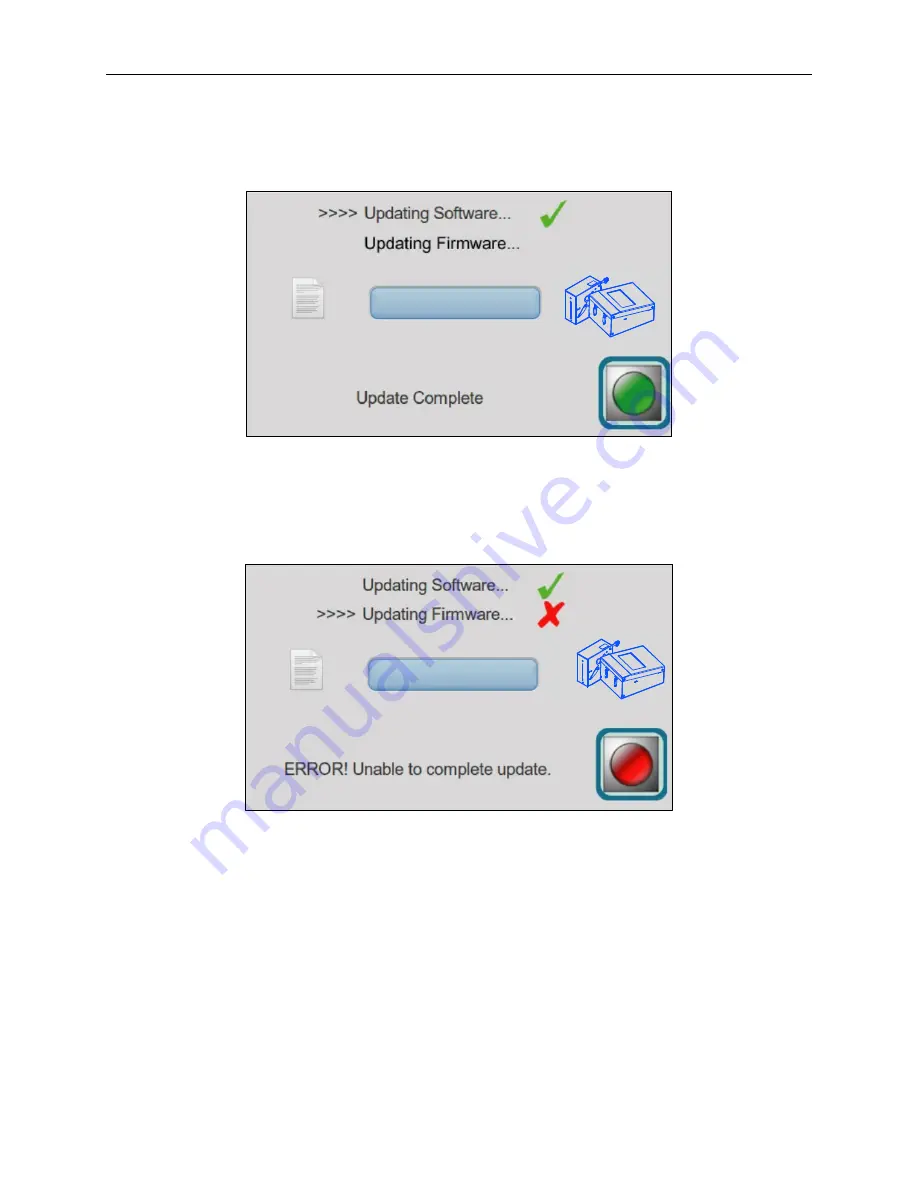

When the update is complete, an “Update Complete” screen will display with a green check next

to the update indicating the update has been successful.

If there is a problem with the update the “ERROR Unable to complete update” screen will

display with a red X mark next to the problem update.

In the unlikely event that there is a problem, remove the USB device containing the update,

power the printer off and on, and then retry installing the update. If the problem persists, call

Squid Ink Manufacturing Technical Support.

Summary of Contents for CoPilot 500

Page 1: ...2005482 Rev G 210505 BETA CoPilot 500 Industrial Inkjet Printing System User Guide...

Page 2: ...2 Abbreviations Terminology 2005995 Rev O 210712...

Page 4: ...4 Abbreviations Terminology 2005995 Rev O 210712...

Page 10: ...10 Abbreviations Terminology 2005995 Rev O 210712...

Page 22: ...22 Introduction 2005995 Rev O 210712 Controller Top View Side View Front View Bottom View...

Page 68: ...68 Installation and Setup 2005995 Rev O 210712...

Page 101: ...Software Interface 101 2005995 Rev O 210712 Custom Keyboard Example...

Page 114: ...114 Software Setup 2005995 Rev O 210712...

Page 128: ...128 Troubleshooting 2005995 Rev O 210712...

Page 141: ...Parts List 141 2005995 Rev O 210712 CoPilot 500 Turbo CoPilot 500 HiSpeed Turbo Controller...

Page 144: ...144 Parts List 2005995 Rev O 210712...

Page 150: ...2005995 Rev O 210712...