8

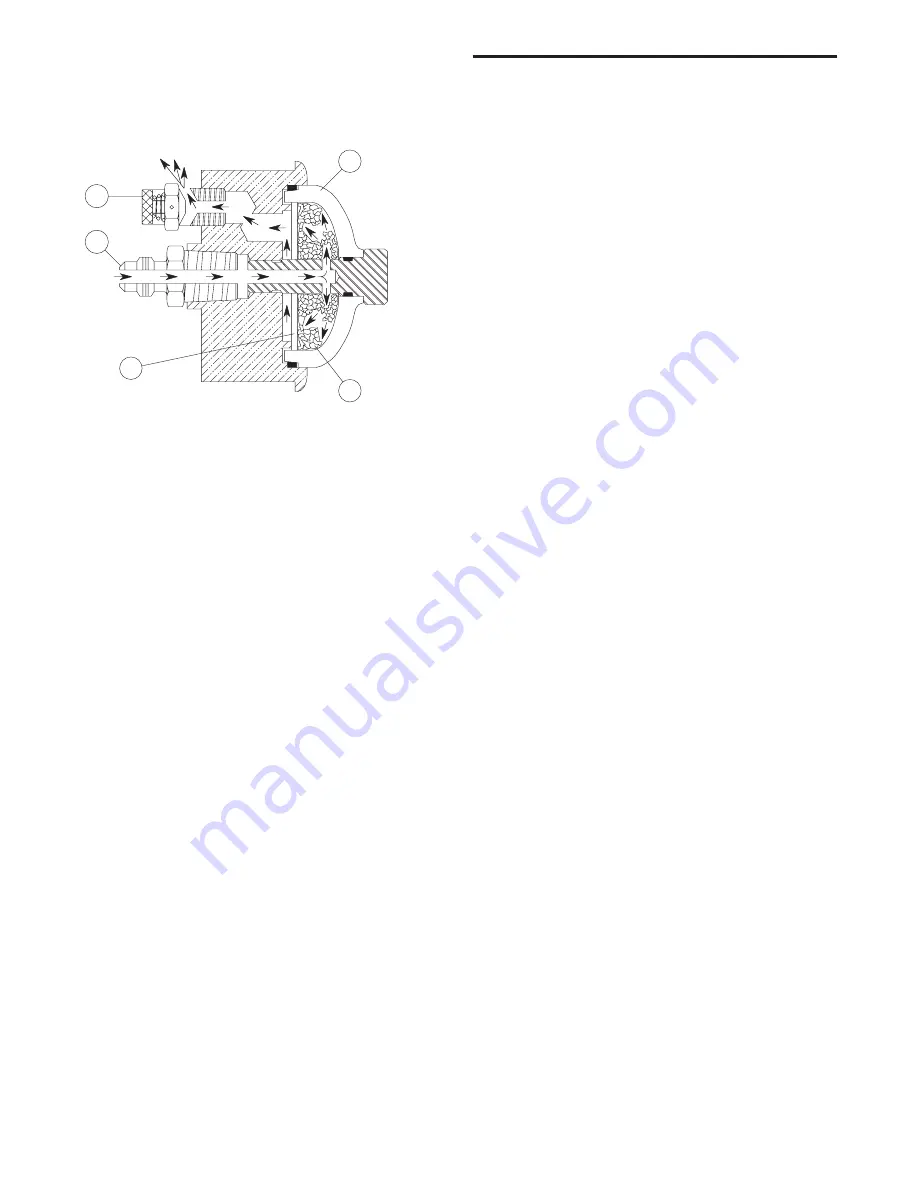

from blue (dry) to pink (wet), alerts personnel of a dryer-

associated moisture problem which requires investiga-

tion. The gas exits the indicator through a porous disc

(4) and then vents to atmosphere through an adjustable

bleed valve (5).

Figure 2

Color Change Moisture Indicator

5.4 Valve Switch-Failure Alarm (Option)

Limit switches are located on each switching valve to

trigger an alarm when any valve is not in the correct posi-

tion. If triggered, the dryer control system will energize

the red alarm LED on the control panel and de-energize

the common alarm relay. The alarm automatically clears

once the alarm conditions are corrected.

5.5 Dew Point Control (Option)

This option monitors and displays outlet pressure dew

points and provides an alarm signal if the dew point

exceeds user-specified set point. Recommended cali-

bration interval is 12 months. Contact the service depart-

ment for details.

Operation – The dew point is measured at the dryer oper-

ating pressure and is displayed in the operator interface.

When the controller is configured for Dew Point Control

mode, the on-stream tower will not switch and regenerate

until a predetermined dew point has been reached. This

elimination of unnecessary heat cycles extends dryer

desiccant and component life.

To protect the dew point transmitter from high tempera-

tures and dew point, a solenoid valve is used to isolate

the transmitter immediately after tower reversal.

If the dew point transmitter fails or reports a reading

outside of its operating range, the display will indicate a

sensor failure alarm condition. If the dryer is configured

for Dew Point Control mode when a transmitter alarm

occurs the controller will revert to the Standard Cycle until

the alarm condition clears.

6.0 Operation

6.1 Controls

A solid-state controller monitors all critical operating con-

ditions, and indicates operating status on a 2-line LCD

display operator interface. The controller receives input

data from temperature sensors, limit switches (option),

the Dew Point Transmitter (option) and the operator

interface. The operator interface displays information

about the dryer operating status and is used to change

the dryer operating mode.

6.2 Operating Modes

6.2.1 Automatic and Manual Advance

The drying and regeneration cycles are divided into

discrete steps. The operator selects either one of the

automatic modes (Fixed Cycle, Standard Cycle or Dew

Point Control) or manual advance mode (Manual Mode)

through the operator interface.

Selecting any of the automatic modes enables the

controller to advance the program step-by-step according

to the programmed schedule.

Setting up the controller for manual advance allows the

operator to advance the program one step at a time. This

mode is used for diagnostic purposes.

6.2.2 Fixed Cycle, Standard Cycle and Dew

Point Control

Fixed Cycle:

Each tower is on-line (drying) for a set

minimum time period.

Standard Cycle:

Each tower is on-line (drying) for a set

minimum time period plus any additional time required to

complete bed heating during low flow conditions. At lower

than design flow rates, the time required for bed heat-

ing will increase which will result in a longer drying time

between regenerations and fewer desiccant heat cycles.

Dew Point Control:

Each tower remains on-line (dry-

ing) until the desiccant bed has been fully utilized. For

lower than designed moisture loads, this results in longer

drying cycles, longer time between regenerations and

fewer desiccant heat cycles. Dew Point Control is an

optional feature.

The operator interface is used to select the operating

mode.