OPERATION

SPT17/20X 86037300 01/24/07

3-4

OPERATION

For indoor use only.

When using the pad, always keep the machine

moving when in contact with the floor.

High starting torque. Hold machine firmly with

both hands.

1. Ensure that the pad driver is in good shape.

Install or change pad if necessary.

2. Plug the machine into a wall outlet as

described in the grounding instructions.

3. Lower the handle by unlocking the adjustment

handle and moving the handle into position.

Relock the handle when it is in a comfortable

position.

Insure that handle is locked in position before

starting machine.

4. Push the safety lock forward, unlocking the

switch levers.

5. With the safety lock forward, squeeze one or

both of the switch levers, turning the machine

on. (These levers can be operated

independently of each other). The safety lock

will not re-engage until both levers are

released.

6. To stop the machine, release the switch

levers.

7. Do not let machine rest on pad. When

finished with the machine, return handle to the

storage position.

NOTE: The machine is equipped with a circuit

breaker to protect the motor in the event an

overload condition occurs. The circuit breaker is

located on the rear of the motor. Push the reset

button to restart the machine. If the breaker trips

again, correct the cause of overloading before

proceeding.

DAILY MAINTENANCE

1. Inspect power cord for wear. To prevent

electrical shock replace cords with frayed or

cracked insulation immediately.

2. Place machine in the storage position.

3. Check pad condition. Change if soiled or torn.

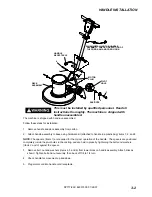

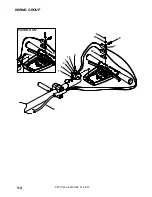

PAD INSTALLATION

1.

Lay machine back, exposing the under side.

!

CAUTION

!

WARNING

!

WARNING

Ensure pad is centered on pad driver. Pull

pad to edge of pad driver in several

directions to check for proper engagement.

NOTE: Use care when replacing center lock

to prevent cross threading.

Summary of Contents for SPT17 10090370

Page 12: ...SPT17 20X 86037300 01 24 07 3 5 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 15: ...WIRING DIAGRAM NOTES SPT17 20X 86037300 01 24 07 4 3 NOTES...

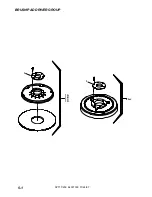

Page 16: ...BRUSH PAD DRIVER GROUP SPT17 20X 86037300 01 24 07 1A 1B 1D 1C 3 3 2A J 5 1...

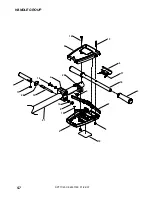

Page 24: ...WIRING GROUP SPT17 20X 86037300 01 24 07 5 9 8 4 6 2 11 6 11 3 1 10 9 7 5 12 PRIOR TO SN...