Note:

If the controller is configured as an

ON/OFF controller the whole group 2

parameters will be occulted and

replaced by:

Hysteresis

0.1 to 10.0% span

0:5

Baude Rate

9600 *

1

4800

2

2400

3

1200

600

0

4

Parity

None

1

Odd

2

Even

3

None*

None*

0

4

User

User

User

Modbus

Jbus

Protoc.

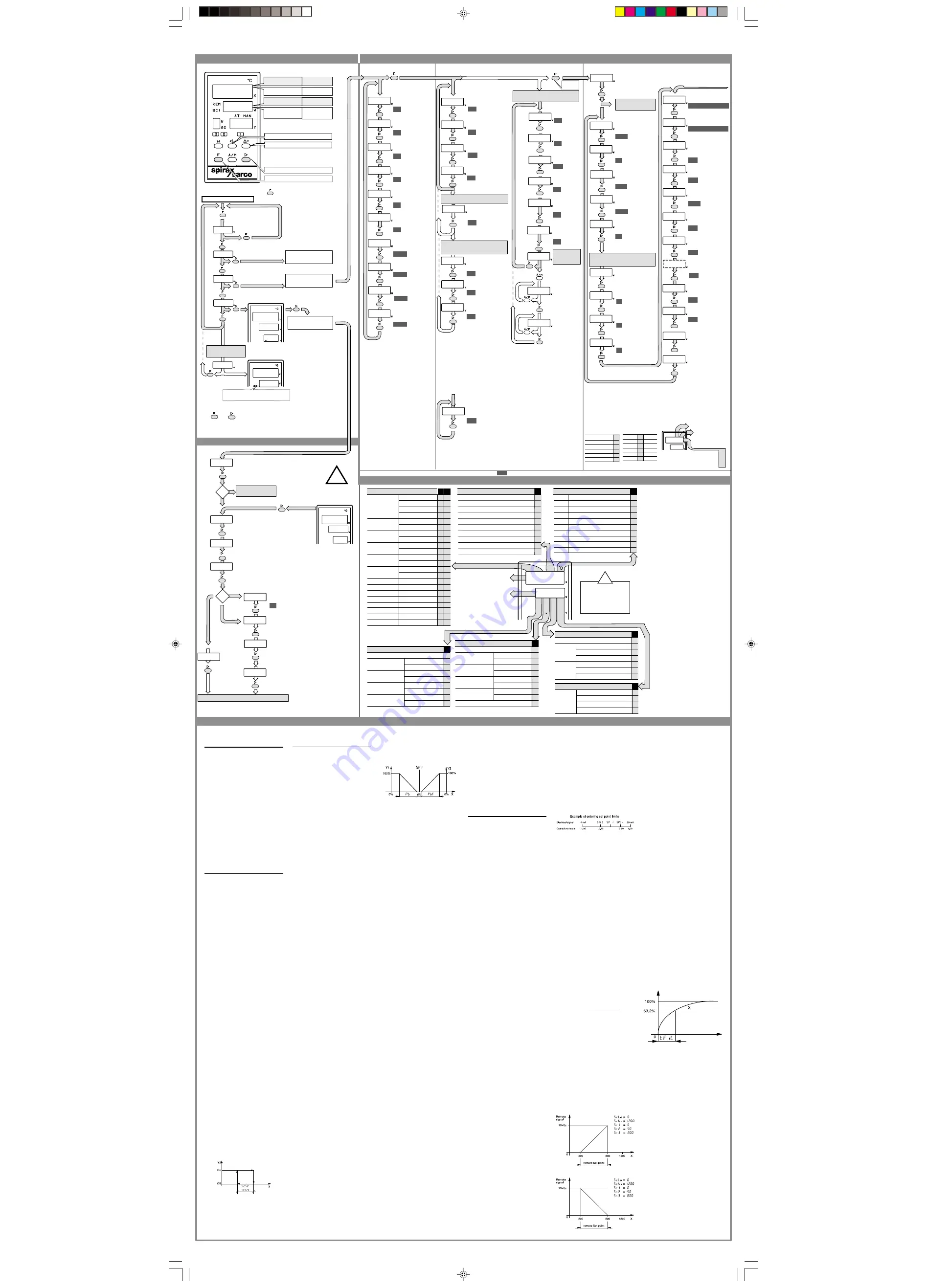

GROUP 1 - SETPOINTS

CONFIGURATION CODE

6•PROGRAMMING INSTRUCTIONS • SX75 SERIES CONTROLLERS

GROUP 3 - ADVANCED FUNCTIONS

PARAMETERS

FUNCTIONS MENU

Loop - Break - Alarm

0.…10 Vdc

9

Type of control action and safety position Y1(3)

0

1

2

3

4

*

5

Reverse

Safety

0%

Direct

0%

100%

100%

-100%

-100%

H

*

(Yh)

(Yh)

(Yh2)

(Yh2)

Reverse

Reverse

Reverse

Direct

Direct

Direct

Direct

Safety

Safety

Safety

Safety

Safety

Safety

Safety

Safety

Safety

Conf

Off

Off

Conf

(4)

(4)

6

7

8

0 to 200 sec

CONFIGURATION

if not configured at

the power-up the

main diplay will

show:

!

Entering the configuration

process

Follow

0 to 200 sec

Event Y2 type

0

1

2

3

4

5

6

7

8

I

Disabled

Deviation with

startup inhibition

Active high

Active low

Band

Active outside

Active inside

Process

Active high

Active low

Deviation

Active high

Active low

Type of control output Y1 (2)

Relay with time-proportioning

1

Logic 0/24 Vdc with time-proportioning

2

4…20 mAdc

3

0…10 Vdc

4

*

6

*

7

4…20 mAdc

*

8

9

G

5

Valve motor drive

Logic 0/24 Vdc with time-proportioning

Relay with time-proportioning

Reverse

9

0

1

2

3

Type of Set point

N

Standard

1 Local

1 Local and Remote 4…20 mA

1 Local and Remote 0…10 Vdc

1 Local + 4 stored

Retransmission output Y4

0

1

2

3

4

5

6

M

None (5)

4…20 mA

Retransmission measurement X

Retransmission Set point W

Retransmission Y1

0…10Vdc

(6)

Retransmission measurement X

Retransmission Set point W

Retransmission Y1 Cool

Event Y3 type

0

1

2

3

4

5

6

7

8

L

9

Disabled

Deviation with

startup inhibitor

Active high

Active low

Band

Active outside

Active inside

Process

Deviation

Active high

Active high

Active low

Active low

1

st

group

2

nd

group

Parameter

protection code

Visible and modification

Visible but NO MODIFICATION

NOT VISIBLE

Security Access

2

1

0

*

0

Relay (On - Off with hysteresis

PARAMETERS DESCRIPTION

Serial

communications

SX75+ only

User

GROUP 2 - CONTROL FUNCTIONS

Press F for

group 3

Press F for normal

operation

To scroll through the menu, press

Normal Operation

Y

Run Auto - Tune

function

Modify or view

Parameters

Start Configuration

Procedure

View

Set point

View

Configuration code

View instrument

Device number 0 … 63

First block of 4

configuration code

E,F,G,H

Second block of 4

configuration code

I,L,M,N

You can configure your

instrument by entering the 8

characters code

*

Only for Heat-Cool applications

Enter correct

Password

1111

From configuration

process

Error: return to

normal operation

Set point

limit low

Beginning of the scale

Set point

limit high

End of the scale

Maximum power

output (heat)

10 to 100%

100

100

Maximum power

output (cool)

10 to 100%

0022

Security access for

parameters (see note)

0000 to 0022

Autotune function

0

Disabled

1

Enabled

0

For serial communication

SX75+ model only

3 Allowable event alarm set points

depend upon the type of alarm

configuration

• Deviation alarm : -300 to +300

• Band alarm:

0 to 300

• Independent:

on full scale

4 Parameters Y2 and Y3 event

a l a r m s w i l l n o t a p p e a r i f

configuration code

I=0 (Y2) and L=0 (Y3)

Note:

factory set parameters

DISPLAY

Measured Value

Set point

Function

mnemonic

during normal

operation

KEYS

Digit select

Increment value

Enter

Function

Function value

during

programming

Input type, scale range (1)

-200…600

°

C

0

0

-200…600

°

C

0

2

-99.9...300,0

°

C

1

0

Conf -99,9...300.0

°

C

1

2

0...600

°

C

2

0

within 0...600

°

C

2

2

0...600

°

C

3

0

0...600

°

C

3

2

0...1200

°

C

4

0

0...1200

°

C

4

2

0...1600

°

C

5

0

0...1600

°

C

5

2

0...1600

°

C

6

0

0...1600

°

C

6

2

eng. units

7

4

eng. units

7

5

eng. units

7

6

eng. units

7

7

E F

RTD

Pt100

IEC 751

Thermocouple J

Fe Cu 45%Ni

IEC 584

Thermocouple L

Fe-Const

DIN 43710

Thermocouple K

Cromel-Alumel

IEC 584

Thermocouple S

Pt10%RhPt

IEC 584

Thermocouple R

Pt13%RhPt

IEC 584

4...20 mA

0...20 mA

0...1 Vdc

0...10 Vdc

Conf.

Conf.

Conf.

Conf.

Conf.

Conf.

Conf.

Conf.

Conf.

Conf.

Yes

Time constant of

the input filter

0 to 30 secs

Input shift

-50 to 50 digit

0

0

1

st

Set point

10

2

nd

Set point

3

rd

Set point

(See Note 1)

4

th

Set point

(See Note 1)

Slope up between the

Set point 0.0 to 100.0

step/min.

(see note 2)

20

30

40

Slope down during

transition of the Set point

0.0 to 100.0 step/min.

(see note 2)

Y2 Event alarm set

point (see note 3)

300

Y3 Event alarm set

point (see note 3)

300

Y

2

Hysteresis

to 10.00% span

0:50

Y

3

Hysteresis

0.01 to 10.00% span

0:50

0:0

0:0

Note:

1 Set points will only be shown

if configuration

code N=3

2 If slope gradient = 0

there will be a step change

between set points

30

Cycling time Y2

(only for heat/cool time

proportional output.)

Only for Heat/Cool controller

(configuration G = 6 to 9)

for serial comms

SX75+ only

Serial Communication status

enabled to write

If

or

is not pressed within 10 seconds the instrument

will time-out back to the process variable.

Note:

1

Enter correct password to start

configuration process (

3333

)

Return to normal

operation

Enter the first block of 4 configuration

codes -E, F, G, H

Number of decimal places EF (Applies

to configuration codes 74 to 87 only)

Configurable input

scale low value

YES

Enter the second block of 4 configuration

codes I, L, M, N

Configurable input

scale high value

For time proportional output

1:0

Dead band

0.0 to 5.0% output

Only for valve motor drive

output (configuration G = 5)

Minimum power

output (heat)

0 to 100%

0

during normal

operation

during

programming

QWtune

2

3

4

u

d

Y1 Safety

( H = 6 or 7)

30

Cycling time Y1

(only for time proportional

output.)

Calibrate

maximum

position of valve

Accept

calibration point

Accept

calibration point

Calibrate

minimum

position of valve

Calibrate

potentiometer

feedback

The valve is driven

to minimum

position

Valve

movement

sensitivity

0.1 to 10%

Time for full

valve travel

15 to 600 sec.

Y2 Event safety

action

0

= disab

led

1

=

closed

contact

2

= open contact

Remote set point

0

= Remote

1

=

Remote

+ local

Remote Ratio

—100 to 100

Remote Bias

sc.Io

…

sc.hi

if at the power-up

you see

9999

-

9999

that means the instrument

IS NOT CONFIGURED

!

2

1

Fuzzy scale

amplitude

0.5 to 999.9%

Fuzzy scale on

change on error

0.10 to 99.99%

Time Sampling

0 to 30 sec.

(0 = 0.5 sec.)

Device Number

0…63

0

Parity

0 to 4 (see note 3)

1

Baud rate

0 to 4 (see note 2)

Serial

Communications

status

0

= OFF;

1

= ON

Proportional band

0.5 to 999.9%

5:0

Integral time

0.0 to 100.0 minutes

1:0

Derivative time

0.00 to 10.00 minutes

0:20

Fuzzy intensitity

0.0 to 90.0%

50

Proportional

band

0.5 to 999.9%

5:0

Integral time

0.0 to 100.0 min.

5:0

Derivative time

0.0 to 10.00 min.

1:00

Fuzzy intensity

0.0 to 90.0%

50

NOTES:

5 For Pt100 and thermocouple inputs with

configurable scale, it advised to select

the largest range possible. The minimum

span should be no less than 25% of the

maximum range. Note: within the selected

range, it is possible to limit the set point low

and high limit settings (Spl l and Spl h).

For mA and Volts inputs, low and high scale

values can be configured in engineering units

between -999 and 9999. The minimum scale

span is 100 steps. The v alues can be

expressed in units (xxxx), in tenth (xxx.x),

hundredths (xx.xx), or thousandths x.xxx).

6 A switch located inside the controller

provides selection of analogue outputs.

See paragraph 4.6 of the IMI

7 The safety state is the value assumed by

Y1 in event of input signal failure it is the

value defining the upper limit of Y1. Safety

states with * (H-4) or (H-5) impose the

maximum limit to Cool action.

8 Selecting H(6,7) it is possible to set

the safety value assumed by parameter say

1 in event of an input signal failure.

9 Configuration code M applies to SX75+

models only.

10 To change from 4...20 mA to 0...10V

alter the jumper switch position.

1:0

Cool relative gain

0.1 to 3.0

60

1:0

20:0

10:00

3

Y3 Event safety

action

0

= disab

led

1

=

closed contact

2

= open contact

sc.Io

10

0

0

Advance to group 3 parameters

OK

1

ERROR

°

C -

°

F selection

(Applies to EF configuration codes 00 to 62 only)

0 =

°

C

1 =

°

F

Y1 Safety

( H = 6 ou 7)

Exiting the configuration process you will access group 3

parameters to modify, if necessary, Set point limits,

maximum power output etc…

F = 0

EF =74…87

F =2

8

4

8

5

8

6

8

7

4...20 mA

0...20 mA

0...1 Vdc

0...10 Vdc

Conf. eng. units with

√

Conf. eng. units with

√

Conf. eng. units with

√

Conf. eng. units with

√

*

Only for Heat-Cool applications

275.8

275.8

4

50

s.p. t

tune

par.

C o n f

Addr

4230

7500

Co

63

Addr

s.p. 2

s.p. 3

s.p. 4

s.p. 1

s1. u

s1. d

y25.p

y HYYy

y35.p

y3Hy

p.b.

t.i.

t.d.

f.1nt.

t.c.

t.c. 2

d.b.

rcr

p.b.

t.i.

t.d.

f.1nt.

t.y.

dy.

pot.1

pot.1

pot.h

pAss

A.par

A.tu.

A.tu.

f.Err

f.der

t.san

s.C.1

Addr

s.C.b.r

s.p.r.1

s...p.l.1

s.p.r.2

s.p.r.3

yl.

yh.

yh. 2

t.fil

1n.5h

sa.y2

sa.y3

s.C.pa

0022

A.par

2

pAss

Con.1

Con.2

C-f

sa.y1

sa.y1

sc.hi

sc.1o

sc.dd

4230

9999

9999

Co

Hy

.

operation

7500

Co

0.01

Entering parameters

When configuration phase is com-

pleted, the controller can display all

the parameters of functions that may

be entered to their desired values. To

simplify the exercise the parameters

have been divided into three groups .

Group 1 covers the parameters re-

lated to the set point. Group 2 covers

control parameters. The third group,

which is protected by the password

1111, are the advanced parameters.

These include the security access,

the fuzzy control parameters, the pa-

rameters for the serial com-

munication, all the limiting functions

and safety states functions.

First group of parameters

s.p.

.1

Stored set point 1 (N = 3)

s.p.

.2

Stored set point 2 (N = 3)

s.p.

.3

Stored set point 3 (N = 3)

s.p.

.4

Stored set point 4 (N = 3)

The memorised set points are the pre-

set values for operation, recalled

through logic inputs, serial transfer or

the front keyboard. When one of these

set values is recalled the small auxil-

iary display on the front of the instru-

ment shows the set number recalled.

sl. u.

Rate of change for increase

of the main set point SP.

Any new value of the main set

point SP greater than that pre-

viously entered set point will

change at the rate entered into

this parameter. The slope is

expressed in digits/minute.

sl. d.

Rate of change for decrease

of the main set point SP.

Any new value of the main set

point SP less than that previ-

ously entered set point will

change at the rate entered into

this parameter The slope is

expressed in digits/minute.

y

Y2sp

Set point of event output Y2

(I = 1 to 8)

y

2Hy

Hysterisis of event output Y2

(I = 1 to 8)

Hysterisis is a zone within which

an output does not change and

maintains the state previously

assumed. In order to obtain a

change in the state of the meas-

ured value X it is necessary to

go outside this zone. The am-

plitude of this hysterisis zone is

expressed as an amplitude %

of the configured scale.

y3sp

Set point of output event Y3

(L = 1 to 8) See

y2sp

y3Hy

Hysterisis of output event Y3

(L = 1 to 8) See

y2hy

Second group of parameters

Hy

Hysterisis of relay output Y1

(G = 0)

The hysterisis is a zone within

which an output does not

change and maintains the state

previously assumed. In order

to obtain a change in the state

of variable X it is necessary to

go outside this zone. The am-

plitude of this hysterisis zone is

expressed as an amplitude %

of the configured scale. The

output contacts are to be found

between terminals 16 and 17.

p.b.

Proportional band (G = 1 to 9)

The band within which the

modulation of the output in di-

rect proportion to the difference

between the set point W and

the measured value. It is calcu-

lated as a % of the input span.

t.i.

Integral time (G = 1 to 9)

This is the time used by a single

integral action to repeat the pro-

portional action. This action is

expressed in minutes.

t.d.

Derivative time (G = 1 to 9)

This is the time taken for a

single proportional action to

attain the same level as the P

+ D output. This action is

expressed in minutes.

f.int

Percentage intensity of fuzzy

action (G = 1 to 9).

The main control output is com-

posed of the sum of two control

algorithms, Fuzzy and PID. This

parameter permits the balanc-

ing as a % of the proportion of the

fuzzy algorithm in relation to that

of the PID. With most applica-

tions the default value of 50%

would be suitable.

tc

Cycle time of the output Y1

(G = 1,2,6,7)

This parameter is expressed in

seconds and defines the total

time of the On/Off states of the

main output Y1 modulated in %

of the PID + Fuzzy algorithm.

e.g. If Y1 = 20% and t.c. = 30”,

the On state = 6” and that of the

Off = 24”.

If G = 1 or 6, the output relay

contacts are between terminals

16 and 17.

If G = 2 or 7, the logic output as

a voltage is available between

the terminals 19(+) and 20(-).

tc 2

Cycle time for “cooling out-

put” Y1

(G = 6 to 9 and M = <> 3, <> 6).

This parameter is expressed in

seconds and defines the total

time of the On/Off states of the

cold output Y1 modulated in %

of algorithm PID + Fuzzy.

e.g. If Y = -20% and tc2 = 30”,

the On state = 6” and that of the

Off = 24”.

The output relay contacts are

between the terminals 17 and

18.

d.b.

The dead band between the

heating and cooling outputs

(G = 6 to 9)

If the variable X coincides with

the set point

sp1

and the out-

put positions itself at 0% the

system will tend to pass con-

tinually between hot and cold

and vice versa. The param-

eter involved defines that the

command at the output of the

controller, whether it is hot or

cold, will only be forwarded if it

is greater than that written in

the same parameter.

rcr

Relative gain of the “cool-

ing” output (G = 6 to 9).

This is a parameter that deter-

mines the amplitude of the pro-

portional band of the cold with

respect to that of the hot:

pbf

=

pb

/

rcr

pbf

= Proportional band out-

put Y1 “cold”

pb

= Proportional band output

Y1 “hot”

ty

Time for full valve travel (G = 5)

for VMD. This is the time used

(expressed in seconds) for the

control valve to travel from its

lower limit to its upper limit. As

a control algorithm of the “float-

ing” type, this parameter is fun-

damental to a correct position-

ing of the control valve.

dy

Resolution of positioning or

dead zone (G = 5).

This parameter expressed in

actuator run %, defines the mini-

mum movement required for

the servomotor. All the com-

mands given by the control al-

gorithm with lower amplitudes

than the value written in the dy

parameter, will not be executed.

pot.1

Procedure for calibration of

the feedback potentiometer.

Only for VMD control (G=5)

This calibration is performed if

the A/M button is pressed. When

the value on the display remains

steady the VMD control valve

has reached its lower run limit.

Pressing the A/M button again,

the controller stores the “0%”

position and drives the control

valve to its maximum position.

When the value on the display

remains steady the VMD control

valve has reached its upper limit.

Pressing the A/M button again,

the controller stores the “100%”

position. At this point the cali-

bration operation is concluded

and to terminate press the “>

enter” button. During the cali-

bration phase it is useful to time

the valve travel time for the ty

parameter.

Third group of parameters

Apar

Secuity access to parameter

groups

This function is used to set the

level of access allowed for

groups 1 and 2.

- 0 Group not visible

- 1 Group visible, without any

facility to modify parameter

contents.

- 2 Group visible, with facility

to modify parameter contents.

Atu

Auto Tune

With this parameter the con-

trollers autotune function can

be enabled or disabled. On

entering “0” the tuning function

is disabled and the “tune” pa-

rameter is no longer available

in the main menu.

f.err

Span of fuzzy operational zone

(G = 1 to 9)

This parameter defines the

zone of operation for the fuzzy

algorithm and is calculated in

% of scale. The optimum value

of this zone can be calculated

using the following formula :

f.err

= 4 x

p.b.

f.der

Fuzzy derivative (G = 1 to 9).

This parameter defines the

speed of the process to be con-

trolled. It is expressed as “ %

scale/minute” and its optimum

value can be calculated with

the formula :

f.der

= 4 x

p.b.

/

t.i.

pb

= Proportional band ex-

pressed as a percentage

ti

= Integral time expressed

in minutes.

t.san

Sampling time (G = 1 to 9)

This parameter determines the

sampling time and is variable

between 1 and 30 seconds max.

The optimum sampling time is

relative to the speed of the proc-

ess to be controlled and is given

by :

t.san

=

t.i.

x 60 /

f.err

pb

=Proportional band expressed in

% of scale

ti

=Integral time expressed in min-

utes. This is automatically cal-

culated during auto-tune.

sCI

Enable or disable serial

communications (SX75+ only)

Addr

Recognition address of serial

communication (SX75+ only)

sCbr

Baud rate of serial communica-

tion (SX75+ only)

sCpa

Parity control of serial commu-

nication (SX75 only)

These four parameters are re-

lated to serial communication,

they only appear during the set-

ting up phase of the instrument

(SX75+ only) and do not relate

to the configuration.

splI

Low limit value for the main

set point SP1

splh

High limit value for the main

set point SP1

The main control set point

sp1

may

only be freely entered between

the two parameters

spll

and

splh

.

spr1

Selects the operation of the

RSP "Remote set point"

(N = 1,2). The target set point

can equal the RSP or the target

set point can equal the local set

point offset by the RSP.

- 0 Target set point = remote

set point

- 1 Target set point = remote

set point + local set point

spr2

RSP Range This parameter is

used to select the range for the

remote set point (N=1,2).

A value from -100 to +100 can

be entered. The value for SPr2

is a percentage of the input

span. A positive value will give

direct action to the RSP. To

calculate the value for SPr2 use

the formula below.

SPr2 =

Input scale range is the value

from the lowest input scale

value (Sclo) to the highest input

scale value (Schi). See RSP

example.

spr3

The datum point for the re-

mote set point (N=1, 2) value

between Sclo and Schl can be

entered. The value entered will

represent the minimum RSP

input signal (0Vdc or 4mA), ie

the start point.

yl

Low limit of output Y1 (G=1 to

4) from 0% to 100%. The value

entered into this paramenter

determines the lowest limit for

output Y1. The safety position

(configuration H) can override

this.

yh

High limit of output Y1 (G= 1

to 9) from 0% to 100%. The

value entered into this param-

eter determines the highest limit

for the output Y1. The safety

position (Configuration H) can

override this.

yl.2

High limit of output Y2 (G= 1

to 9) from 0% to 100%. The

value entered into this param-

eter determines the highest limit

for the output Y2. The safety

position (Configuration H) can

override this.

tfil

Input Filter This parameter can

be used to stabilize the meas-

ured value. The value entered in

this parameter defines the time

constant of the digital filter used

on the measured value X. Given

an instantaneous variation be-

tween 0% and 100%, measured

value X will reach 63.2% in the

time indicated in the parameter

tfil

.

The affect of the time constant

tfil

on the measured value X

Insh

Input Shift This parameter al-

lows the user to adjust the meas-

ured value reading. The value

entered in the parameter will be

used as the offset from the meas-

ured value. The settings are +/-

50 digits.

say2

Safety state of event Y2

(l = 1 to 8)

If the measured value signal

fails, event output Y2 can be

set to:

- 0 Function excluded. Normal

operation of alarm respected.

- 1 Output held in the On state.

- 2 Output held in the Off state

say3

Safety state of event Y3

(l = 1 to 8)

If the measured value signal

fails event output Y3 can be set

to:

- 0 Function excluded. Normal

operation of alarm respected.

- 1 Output held in the On state.

- 2 Output held in the Off state.

RSP range

Input scale range

x 100

S.P.L. h

flyout_section.pmd

7/12/02, 4:43 PM

1