IM-P703-05

CTLS Issue 3

EP6 Positioner

3.2 Non-explosion proof type

4. Adjustments

Controller

(AO)

(DCS/PLC sourcing

output card)

Ground

Ground (M4)

Ground (M4)

Spare bolt

(M4)

Black

Red

Auto

manual

switch

Manual

Auto

4.3 Adjustment – A/M switch (Auto/Manual)

4.3.1

Auto manual switch is located on the top of pilot unit. Auto

manual switch allows the positioner to be functioned as by-

pass. If the switch is rotated counterclockwise (toward “M”,

Manual), then the supply pressure will be directly supplied to

the actuator through Out1 port of positioner regardless of input

signal. On the other hand, if the switch is turned clockwise

(toward “A”, Auto), then the positioner will operate normally by

input signal.

4.3.2

Make sure that the supply pressure does not exceed the rated

pressure level of the actuator before the switch is loosened

toward “M”.

4.3.3

After using the “Manual” function, return the auto manual switch

to “Auto”.

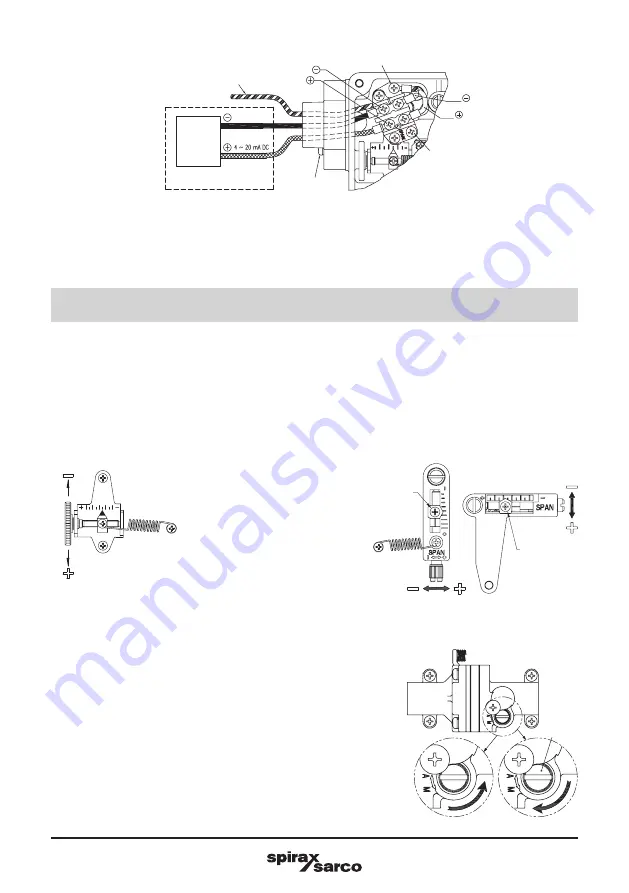

4.1 Adjustment -

Zero Point

Set input signal at 4mA (or 20mA)

as the initial current, then rotate

the adjust wheel of zero setting

unit upward or downward to set

actuator’s zero point.

Please refer to the figure below.

Lock

screw

Lock screw

4.2 Adjustment - Span

4.2.1

After setting zero point, supply input signal at 20mA (or 4mA) as the end point

current and check the actuator stroke. If the stroke is low, the span should be

stretched. If the stroke is high, the span should be reduced.

4.2.2

Changing span will affect zero point setting so zero point should be set again

after span has been adjusted.

4.2.3

Above two steps are

required several times

until both zero and span

are properly set.

4.2.4

After proper setting,

tighten lock screw of the

span unit.

2.2.2

Piping and cam direction setting

for rotary double actuator