4. Maintenance Instructions

The pressure tank unit is entirely maintenance-free.

If the pump gets blocked it will first have to be rinsed out.

Connect the pump after removing delivery pipe to the

water pipe and let water flow into the suction pipe.

While water is flowing into the pump, engage it several

times for about 2 seconds.

In this way it is possible to eliminate most blockages.

J5C74A48B0A8B:>55A>BCC74?D<?70BC>144<?C843

completely.

J-74=C74?D<?8B=>C6>8=6C>14DB435>A0;>=6C8<4

for instance in the winter period, it is recommended to

rinse out the pump thoroughly with water, empty it

completely and store it in a dry place.

J 742: F74C74A C74 ?D<? F>A:B 5A44;H 1H 1A845;H

connecting and disconnecting it.

J*74=58;;C74?D<?0608=F8C7C7434;8E4AH;8@D830=3B4C

it up for use.

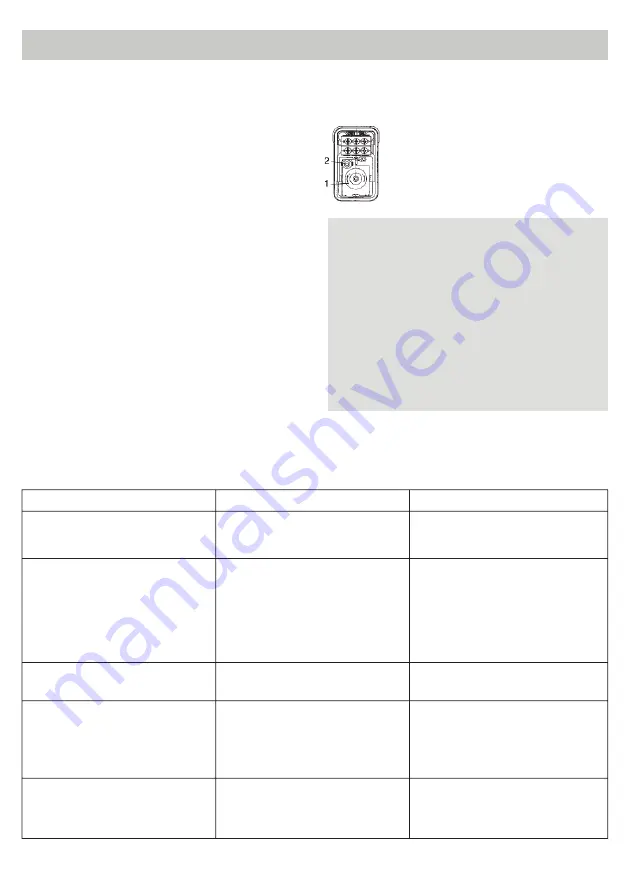

Adjusting connection and cut-off pressure.

The pressure tanks unit are factory set with an operating

pressure of 1,4

8

2,8 or 1,6

8

3,2 bar (see table of

specifications). The connection and cut-off pressure can

be adjusted and may be set the desired pressure onto

according to your need by means of the switch (see

figure).

1 = Connection pressure

2 = Cut-off pressure

Take the protective cover off the pressure

switch. With a screwdriver, turn onto - or +

according to need. Check the pressure with

the pressure gauge.

CAUTION!

In order to work, the pump must always be filled

with the delivery liquid until it overflows!

Caution: The pump must never run dry. The

manufacturer’s warranty is null and void in the

event of damage to the pump caused by its running

dry.

Check that the pump is airtight; piping that is not

airtight draws in air preventing the pump from

working properly.

If it is not possibile to eliminate the trouble, please call our service department.

To avoid damage during transport, please ship in the ORIGINAL PACKING.

5. Troubleshooting Table

Trouble

Cause

Remedy

Motor will not start

Pump will not suck

Insufficient rate of flow

The thermal cut-out switch cuts

off the pump

J $><08=BE>;C064

J &D<?8<?4;;4A90<<43

Thermostat detached.

J 742:E>;C064

J 8B<0=C;4C74?D<?0=32;40=8C

J )D2C8>=E0;E4=>C8=F0C4A

J &D<?270<14AF8C7=>F0C4A

J 8A8=BD2C8>=?8?4

J )D2C8>=E0;E4=>C08AC867C

J )D2C8>=A>B4BD2C8>=E0;E42;>6643

J #0GBD2C8>=74867C4G244343

J &DCC74BD2C8>=E0;E48=C>F0C4A

(min. 30 cm.)

J &>DAF0C4A8=C>C74BD2C8>=D=8>=

J 742:C74B40;>5C74BD2C?8?4

J ;40=C74BD2C8>=E0;E4

J ;40=C74BD2C8>=A>B4

J 742:C74BD2C8>=74867C

J )D2C8>=74867CC>>7867

J 8ACHBD2C8>=A>B4

J -0C4A;4E4;50;;B@D82:;H

J &D<?5;>FA0C4A43D2431H5>A486=

bodies.

J 742:BD2C8>=74867C

J ;40=C74BD2C8>=A>B4

J )4CC74BD2CE0;E4;>F4A3>F=

J ;40=C74?D<?0=3A4?;024C74F>A=

parts.

J #>C>A>E4A;>0343

Friction too great due to foreign bodies.

J ;8<8=0C4C745>A486=1>384B

Wait for the thermal cut-out switch to

CA8664A0608=0??A>G<8=B

Pump connects with very low

water intake

J &A4BBDA4>508A2DB78>=8=C7434;8E4AH

tank too low.

J

Increase the pressure of the air cushion

in the filling valve (1.5 bar)

15

Summary of Contents for AGC 1100/25

Page 65: ...NOTES ...

Page 68: ...COD 7106980 REV 16 04 2017 ...