3.4 ENVIRONMENTAL CONDITIONS

4.2 PREPARATION

On receiving the product: remove the packaging and display the material so that all is visible.

The appliance must be checked before every use so as to reveal any working abnormalities and/or damage caused by transport and/or storage.

4 OPERATING INSTRUCTIONS

4.1 TRANSPORT AND STORAGE

Before transporting the appliance, make sure that it is correctly packaged ensuring also that there are no risks of shocks or falls during the tran-

sport itself. Keep the original packaging for any eventual further transport. Damage to the appliance caused during transport and handling is not

covered by the guarantee. Repairs or replacement of the damaged parts are the responsibility of the Client. The appliance must be stored in a

dry place free from humidity.

During stockage, make sure not to place any heavy materials on top of the Z4002; the device should not be considered a support, if not for the

employment is has been designed for.

For both operation and stockage: from -20°C to +60°C

4.3 FUNCTIONING

Before every use, make sure to check the following points scrupulously:

•

General functionality of the device

•

Fixation of nuts and bolts

•

Use of wheels and breaks

•

Spring release

3.3 TECHNICAL DATA

Minimum heigth

Maximum height

Intermediate height

Lenght

Width

Weight

Capacitiy

550mm

850mm

795mm

1350mm

620mm

25 +/- 3%

250Kg

Wheels Ø200mm

Frame Material

Supporting Frame

Finish

Polyamide core

Polyurethane foam wrap

Sphere bearing in Stainless Steel

Stainless Steel AISI 304

tube Ø35x1,5mm Stainless A304

tube 25x15x1,5mm Stainless A304

Electro Shine Finish

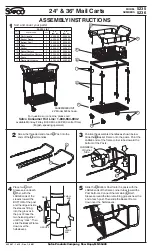

4.3.1 Loading the coffin for working bench use of the device

In this phase at least two physically suitable operators are needed

1. Insert the brakes of the wheels of the Z4002

2. The operator has the possibility to replace the anti-vibrating rubber supports with the nails (to be find under the tube) by simply (un)screwing both

accessories; both allow the levelling of the bench, assuring stability and safety

3. Fold the roller supports in unloading position (inwards, in the direction of the space dedicated to the fork lift Fig. 2)

4. Load the coffin on top of the device, making sure to distribute the weight of the load in a balanced way

The central part of the device is dedicated to an easy positioning of the coffin by fork lift (Fig. 2). Two operators are needed anyway

4.3.2 Transport and unloading the coffin

In this phase at least two physically suitable operators are needed

1. Unblock the brakes

2. Activate the rotating supports, making sure the rolling system supports the bottom of the coffin with a rotation in outside direction

3. When close to the van, if previously inserted, unblock the rolling system with the apposite levers on both sides, in order to allow a natural rolling

of the coffin

4. Roll the coffin into the van, paying attention to its balance and the linear movement set up by the trolley's rolling system

4.3.3 Height management

In this phase no load may be placed on the device

4.3.3.1 In order to obtain an intermediate height, starting from the maximum height, turn the 4 upper knobs (Fig. 1 - n ° 5) in the direction indica-

ted by the arrows in order to unblock the system; move the upper structure downwards and block it with the same knobs, turning them in opposi-

te direction.

4.3.3.2 Obtaining the minimum height, starting from the maximum heigth:

1. Unblock the 4 upper knobs (Fig. 1 - n ° 5);

2. Remove the upper structure of the Z4002;

3. Unblock the 4 lower knobs of the extensions (Fig. 1 - n ° 4) by turning them in the direction indicated by the arrows;

4. Remove the 4 extensions;

5. Insert the upper structure on the lower structure without the removed extensions;

6. Fix the 4 knobs in the apposite holes by turning them.

3

Fig.2

Fig.3