8

Legislative Decree 25/01/2010, n. 35

Modifications and additions to the 20/02/97 Decree n. 46

UNI EN ISO 14971

Application of risks managing to medical devices

UNI CEI EN ISO 15223-1

Medical devices - Symbols for use in the medical device labels,

labelling and information to be provided. Part 1: general requirements

UNI CEI EN 1041

Information supplied by the medical devices manufacturer

CEI EN 62366

Medical Devices - Application of the utilisation characteristics of

engineering to medical devices

MEDDEV 2.4/1a-b

Guideline for the classification of medical devices

NB-MED 2.5.1/Rec 5

Technical Documentation

MEDDEV 2.7.1

Clinical Data

MEDDEV 2.12/1

Medical Devices vigilance system

UNI EN 14155

Clinical evaluation of the medical devices for human beings - Part 2:

Clinical evaluation plans

3.6

Environmental conditions

Functioning temperature:

from -15 to +50 °C

Storage temperature:

from -20 to +60 °C

4

OPERATING INSTRUCTIONS

4.1

Transport and storage

Before transporting the appliance, make sure that it is correctly packaged ensuring also that there are no risks of shocks,

bumps or falls during the transport itself. Keep the original packaging for use in case of any further transport and for storage.

Damage to the appliance caused during transport and handling is not covered by the guarantee. Repairs or replacement of

the damaged parts are the responsibility of the client. The device must be stored in a dry, cool area away from direct

sunlight. It must not be placed in contact with any substances or chemical agents which could cause damage and reduce

safety characteristics.

During storage, do not placed heavy materials over the device. The chair should not be considered and used as a shelf for any

type of material.

4.2

Preparation

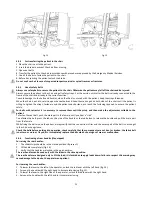

On receipt of the product:

Remove the packaging and display the material so that all components are visible.

Check that all the components/pieces on the accompanying list are present.

The appliance must be checked before every use so as to reveal any working abnormalities and/or damage caused by

transport and/or storage. In particular, check:

General functionality of the device

Cleanliness of the device (remember that the failure of cleaning may cause the risk of cross infections)

Absence of cuts, holes, tears on the structure, including the straps

Correct fixation of all nuts, bolts and screws

Correct fixation of straps

Correct fastening of straps

State of use (moving parts, wheels, belts)

Integrity of sewings and sheets

No piping or metal sheet present bends or cracks

The seat and the backrest do not present any lacerations and cuts

Weldings are intact, without any cracks or breaks

The seat belts, sheets, moving parts, wheels and handles are intact and functioning

The wheels are fastened securely, are stable and running

The wheels are free of debris

The front-wheels are self-positioning (if equipped)

The brake works correctly and is operated simultaneously

The device opens and locks

The device closes automatically

The slides open

The slides are automatically closed (if equipped)

The belts of the sleds run and have always the correct tension for being used

Functioning of springs

The control system ESC can be selected (if equipped)

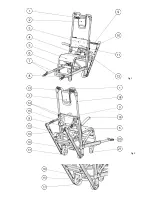

Summary of Contents for EVA

Page 6: ...6 Fig 1 Fig 2 ...