SpectraPure

SpectraPure®Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281

®

14

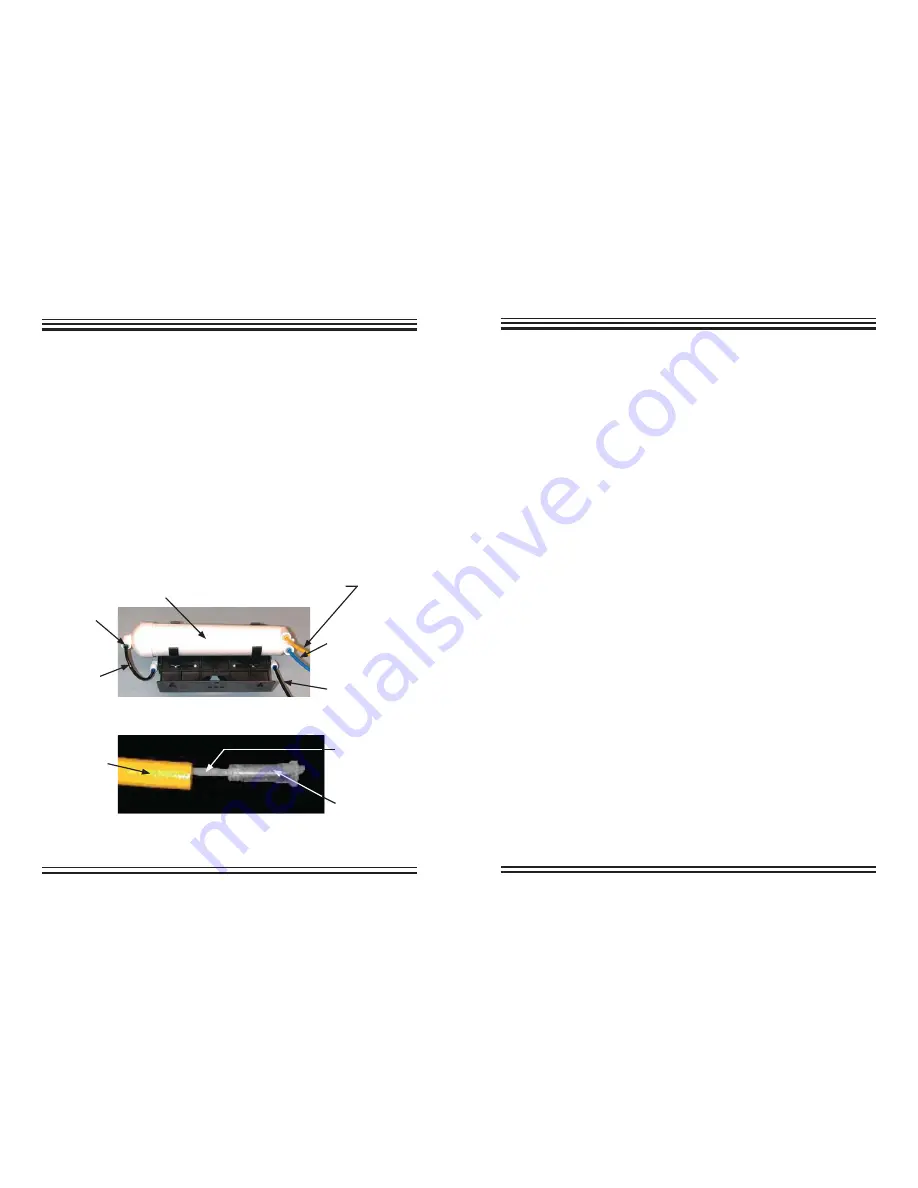

6. Re-insert the yellow tubing into its push-fitting in the RO membrane as

follows:

a.) Moisten the O-ring seal inside the concentrate outlet fitting by dripping

a few drops of clean water into the fitting.

b.) Grasp the yellow tubing near the flow restrictor end, and insert the

tubing into the push-fitting. Push the tubing into the fitting until

resistance is felt, approximately 1/2 inch (12.7 mm). The tubing is now

resting on the O-ring seal inside the fitting.

c.) Firmly push the tubing approximately an additional 1/4 inch

(6.35 mm) further into the fitting to completely seat the line into

the fitting and O-ring seal.

7. Turn on the system water supply and check for leaks prior to further use or

testing. If a leak is observed, you may not have pushed the yellow tubing

into the push-fitting far enough to seal the tubing against the O-ring. Turn

off the system water supply and reseat the tubing as described above.

yellow tubing

capillary tubing

plastic insert

Fig. F: Flow Restrictor Assembly

Fig. E: Reverse Osmosis Assembly

Top/Rear View

membrane

feed

push-fitting

black

tubing to

membrane

feed

RO membrane

yellow concentrate tubing

blue purified water

tubing

black feed water

tubing

(Waste Water)

(Good Water)

(Tap Water)

SpectraPure®Inc

.

Fax 480.894.6109 Fax us toll-free 1.877.527.7873

E-mail: [email protected] Visit us on the web www.spectrapure.com

15

SpectraPure

®

SEDIMENT PRE-FILTER REPLACEMENT

For maximum contaminant removal and long membrane life, the sediment and

carbon pre-filters must be changed when a 15-20% drop in pressure is observed

OR at least 6-month intervals. If your water contains a great deal of sediment or

chlorine, the pre-filters may require more frequent changes to maintain adequate

production rate and extended membrane life.

Sediment Pre-Filter Replacement

Materials Required:

0.5-micron MicroTec™ Sediment Filter (SF-MT-0.5-10), Filter

Wrench

Procedure:

1. Turn off water supply to the system.

2. Refer to photo on page 8. Using the provided filter wrench, remove

the first housing on the left. Unscrew it counterclockwise as viewed

from

the

bottom.

3. Remove the old filter and discard.

4. Thoroughly wash the housing with a mixture of hot soapy water and a

few teaspoons of household bleach. Rinse well with clean hot water.

5. Install the new pre-filter onto the round port on the head of the

housing,

Screw the housing back onto the assembly, and hand tighten

only

.

NOTE: Do not use filter wrench to tighten housings. Over-tightening will

damage housings and void your warranty.

6. Proceed with carbon block filter replacement.

CARBON BLOCK FILTER REPLACEMENT

For maximum contaminant removal and long membrane life, the sediment and

carbon pre-filters must be changed when a 15-20% drop in pressure is observed

OR at least 6-month intervals. When chlorine breakthrough greater than 0.1

ppm occurs in the yellow concentrate line, test for chlorine breakthrough by

collecting a 10 ml sample of the concentrate from the yellow tubing and test the

chlorine concentration using test kit TK-CL-25. If the chlorine concentration is

Materials Required:

0.5 micron Carbon Block Filter (CF-0.5-10), Filter Wrench,

Chlorine Test Kit (TK-CL-25)

Procedure:

1. Perform steps 1-5 listed above

2. Turn on system water supply and check for leaks.