33

Spectra High Pressure Tube Fitting Assembly Instructions

Carefully fit and measure the tubing before cutting with a sharp razor knife or hose cutter. Remove any

burrs from tube ends. Route tubing away from excessive heat sources and secure from vibration and

chafe. Have at least one shallow bend in the tube assembly after it is installed. The minimum tubing bend

radius is 6 inches (15cm).

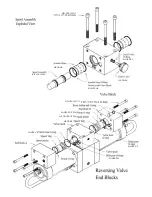

Refer to figure 1:

If a fitting has been disassembled, reassemble as illustrated. The notch on the ferrule

must engage the inside of the nut properly for the nut to seat down fully. Once the tube is inserted the

ferrule and nut will naturally align.

Refer to figure 2:

Insert tube fully into the fitting—it should go in 0.9” (23mm)—once tube goes past the

grab ring it is locked in position. Tighten the nut finger tight while moving the tube around to prevent

binding. One thread should be showing under the nut. Secure the tube so it won’t back out when

tightening.

Refer to figure 3:

Use a 13/16” wrench to hold a straight body fitting or a 3/4” wrench for a 90º body.

Use a 7/8” wrench for the nut. Hold the body, recheck the tube insertion, then tighten the nut 1-2/3

turns. Use the index mark on the nut as a guide. The threads should be completely covered by the nut.

Make sure these fittings are tight on initial assembly or they will fail!

The correct torque

specification is 85 foot pounds.

Summary of Contents for AQUIFER 150

Page 2: ...2...

Page 4: ...4...

Page 32: ...32...

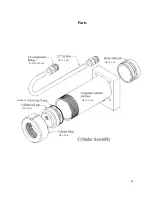

Page 40: ...40 Parts...

Page 41: ...41 PL MTS 3 8X1 2S HP CYL SST HP CYL CCA SO HPP ECCB HP CYL EC HP CYL R HP CYL PT Parts...