Operating Instructions

16

1096.0799 | VU / VH Series

10/2010

5.6.3

Specifying pipe lengths

1.

Dimension the suction, pressure and operating liquid pipes

as short as possible.

2.

Increase the pipe cross-sections when using long suction,

pressure and operating liquid pipes.

The pressure pipe must not rise more than 1 m vertically or

diagonally upwards.

5.6.4

Changes in cross-section and direction

1.

Avoid radii of curvature of less than 1.5 times the nominal

pipe diameter.

2.

Avoid sudden changes of cross-section and direction along

the piping.

5.6.5

Safety and control devices

5.6.5.1 Avoiding

contamination

1.

Integrate low-resistance filters in the suction pipe.

2.

Install a differential pressure gauge with contact manome-

ter to monitor the contamination process.

5.6.5.2 Avoiding

backflow

►

Install a ball check valve between the suction pipe and the

suction connection of the aggregate to prevent operating

liquid from flowing back into the suction pipe after aggre-

gate shut-down.

5.6.5.3

Provisions for isolating and shutting off pipes

For maintenance and repair works

►

Provide for shut-off devices in the suction, pressure and

process water pipes.

5.6.5.4

Provisions for measuring operating conditions

1.

For pressure measuring: provide for manometers in the

suction and pressure pipe.

2.

Provide for a power sensor at the motor side.

5.7 Connecting

pipes

5.7.1

Providing for clean piping

CAUTION

Risk of material damage caused by pump/aggregate con-

tamination!

►

Make sure contamination does not enter the

pump/aggregate.

1.

Clean all piping parts and fittings prior to assembly

2.

Make sure no flange seals project inwards.

3.

Make sure no sealing material (sealing tape, adhesive)

projects inwards.

4.

Remove any blank flanges, plugs, protective foils and/or

protective paint from the flanges.

5.7.2

Installing suction pipe

1.

Remove the transport and sealing covers from the

pump/aggregate.

2.

Avoid air pockets: lay out the pipes with a continuous slope

down to the aggregate.

3.

Make sure no seals project inwards.

4.

Make sure no sealing material (sealing tape, adhesive)

projects inwards.

5.

Install a ball check valve in the suction pipe to prevent

operating liquid from flowing into the suction pipe at stand-

still.

5.7.3

Installing pressure pipe

1.

Remove the transport and sealing covers from the

pump/aggregate.

2.

Install the pressure pipe.

3.

The pressure pipe must not rise more than 1 m vertically or

diagonally upwards.

4.

Avoid air pockets: lay out the pipes with a continuous slope

from the aggregate.

5.

Make sure no seals project inwards.

6.

Make sure no sealing material (sealing tape, adhesive)

projects inwards.

5.7.4

Stress-free pipe connection

For the layout of piping, observe VDMA standard sheet

24277 on stress-free pipe connections.

5.8 Fine adjustment of coupling

CAUTION

Risk of material damage caused by improper coupling ad-

justment!

►

Accurately adjust the motor to the pump in case of height,

lateral or angular offset.

►

For detailed information and special couplings:

(

Manufacturer's specifications).

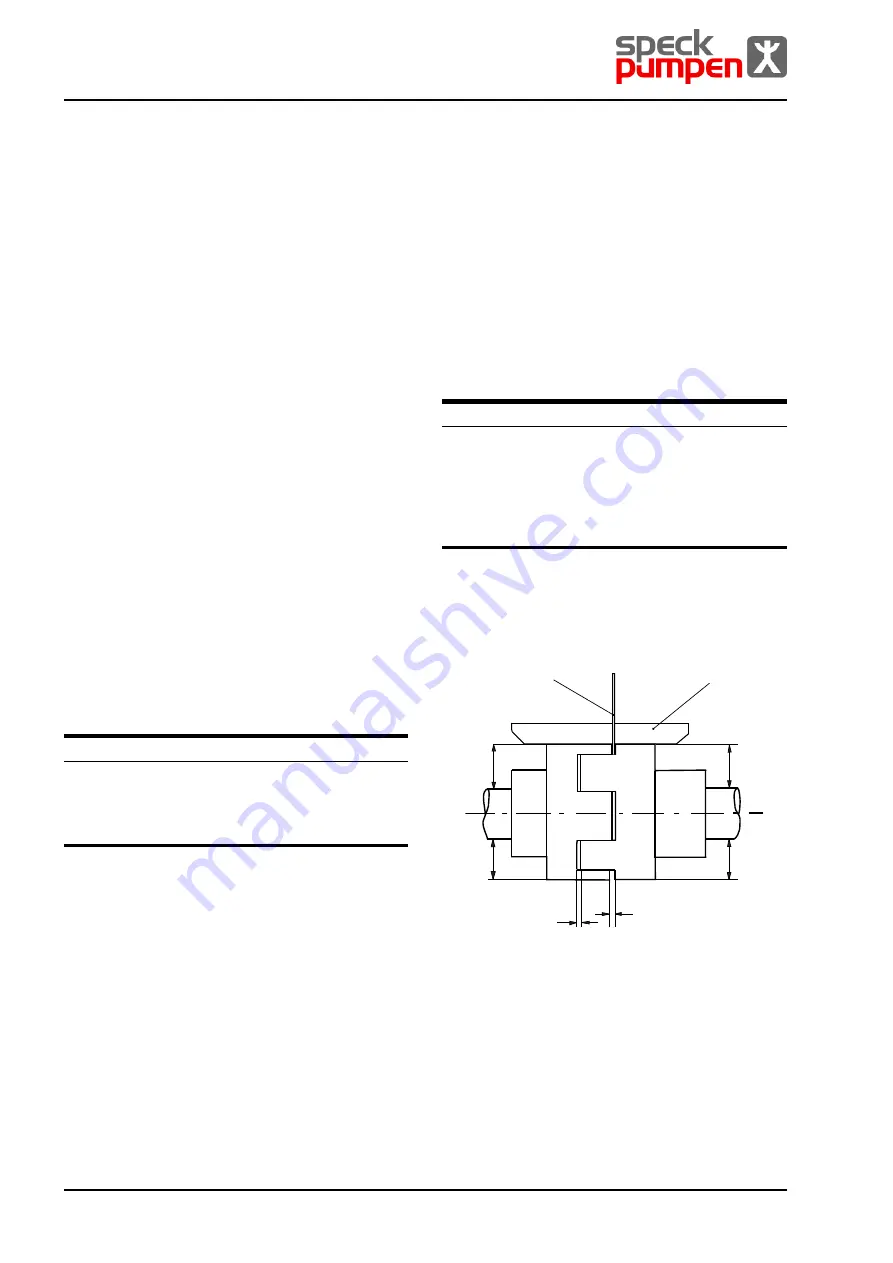

5.8.1

Checking coupling adjustment

Auxiliary means, tools, material:

feeler

gauge

straightedge

dial gauge (possible with couplings with spacer)

other suitable tools, e.g. laser adjustment tool

2

B

B

A

A

S

S

1

1 Gauge

2 Straightedge

Fig. 12 Checking coupling adjustment