BEF320-2A

Operating Manual

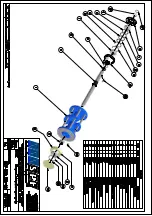

Height Adjustment Maintenance:

Ensure the height screw thread is cleaned and then lightly oiled. Periodically it should be removed

and the female threaded section cleaned out and oiled. At the same time the self-aligning bearing

should be greased.

The clevis pin should be oiled regularly to maintain a light, smooth height adjustment.

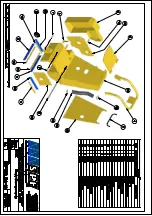

BEF320 Cutter Drum Adjustment:

Should the machine be cutting more heavily on one side. Stop engine. Adjust lock/nut bolt

assembly on top of right hand side of chassis. By adjusting up or down the cutting action can be

reset level again. Retighten all bolts. Test on sample area and if required reset until cutting

correctly.

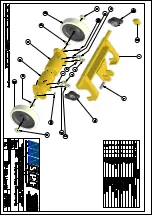

Great care should be taken to ensure belts have correct tension and also correct alignment.

Serious damage could be caused to the drive shaft, drive shaft bearings and engine if the belts

are excessively tight.

Note: Never operate the BEF320 without belt guard fitted

4

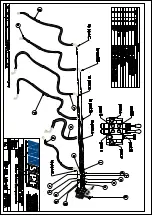

Level Adjustment

bolt and lock nut

Slacken before

adjusting.

Tighten before

use.