BEF320-2A

Operating Manual

MAINTENANCE

PRIOR TO ANY MAINTENANCE OR ADJUSTMENT STOP ENGINE.

After use:

Clean the machine to remove all build up of dust and surface residues.

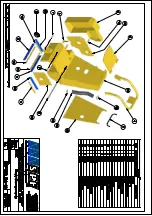

Drum Removal:

Remove bolts on side plate and then screw two bolts back into the two tapped holes in the side

plate. Continue winding in and this will push side plate off dowel pins. Pull off side plate remove

key from shaft. Pull out cutting drum. Fitting a new cutter head is simply a reversal of the above

procedure, a little care must be taken to align the drive shaft, cutter drum and support end drive

bush.

EXCESSIVE FORCE SHOULD NOT BE NEEDED TO REFIT THE CUTTER DRUM.

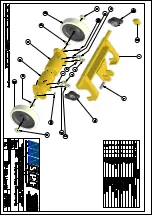

Cutter Drum Maintenance:

When changing cutter drum always check that the flail shafts are not worn with pronounced

grooves and also that the centres of cutters and spacers are not elongated and beginning to

"mushroom". The drum assembly is hitting concrete with great force 650 times every minute!

Expenditure on consumables must be expected and built into all job costing.

While changing the drum the condition of the drive shaft and side plate bearings should be

checked. If any roughness, side play or leakage of grease is detected then new bearings should

be fitted. Lightly oiling the drive shaft will prevent a build up of rust which could cause difficulty

when changing the drum. At the same time check belt tension and condition also checking the

pulley grooves are clean and undamaged.

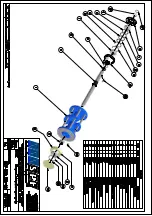

The drive shaft is manufactured from high quality steel to produce the special properties required.

The shaft is extremely strong and virtually unbreakable when used as intended. If however

sideways pressure is exerted on the shaft while it is not supported by the side plate bearing it can

be bent.

With the drum removed check that the vacuum port is free from blockages and that the dust skirts

are in good condition.

Remove all build up and deposits of material from the under side of the drum housing. On certain

applications, e.g. the removal of damp self levelling compounds, it may be necessary to clean

away deposits hourly! Failure to do so could result in overload of the drum assembly, engine and

drive belts

Cont’d

……

3