4

ID# M88724C1

08/06

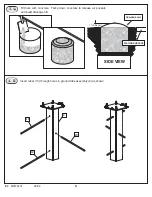

Item #5 (4)

Item #34 (4)

Item #24 (9)

Item #7 (4)

Item #28 (3)

Item #20 (1)

Item #23 (1)*

Item #25 (8)

Item #26 (1)

Item #22 (9)*

Item #8 (1)

Item #9 (1)

HARDWARE IDENTIFIER (NUTS, WASHERS & SPACERS)

HARDWARE IDENTIFIER (BOLTS & SCREWS)

Item #27 (1)

Item #19 (26)

HARDWARE IDENTIFIER (OTHER—NOT ACTUAL SIZE)

Item #21 (16)

Item #6 (4)

Item #33 (2)*

Item #15 (4)*

Item #29 (4)