14

Southworth Products

FPS3000-43NAS Manual

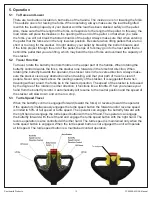

5.4 Electric Brake

Your stacker is equipped with an electric magnetic brake. The brake is applied when the handle is

in its vertical position between 10 – 15 degrees and lowered position between 80 – 90 degrees.

The brake could be released when you pull down the handle at any point between 15 – 80

degrees. Always make sure the brake is released before operating the stacker. When the stacker

is running, you could brake the stacker by raising the handle to its vertical position or lowering the

handle to its lowest position. Or, to turn the butterfly controls in the opposite direction, the change

in direction of the motor will slow down, stop, and reverse the direction of stacker. When parked,

the handle will spring back to the full vertical position with the brake applied and the forks in

lowered position.

5.5 Reversing Safety

At the end of the handle there is a large, red reversing bar (belly button switch) that is designed to

protect the operator from injury. When the operator runs the stacker backwards, and the end of the

handle comes in contact with the operator’s body, the stacker will automatically reverse direction

and travel away from the operator. When the reversing safety bar comes in contact with your body

during operation, immediately release your hands from the butterfly control and put the handle up

to its vertical position or down to its lowest position and the brake is on. The reversing safety bar

will automatically resume to its original position after being activated.

5.6 Horn

As standard equipment, a horn that is located on the top of the handle.

6. Maintenance & Repair

DO NOT USE LIFT IF IT IS NOT OPERATING PROPERLY, OR APPEARS

UNSAFE IN ANY WAY!

All maintenance to be performed with the forks fully lowered.

Turn off the key and disconnect the battery before performing any

maintenance.

6.1 Before Each Use

• Check for corroded and loose battery terminals. A white powder substance will be present if

there is any existing corrosion.

• Visually inspect for any cracks or damage to the casing.

• Check for loose battery tie-downs.

• Inspect wire connections on the battery charger. Check power cord for nicks/damage.

• Check power charger for proper mounting.

• Inspect pump and cylinder for oil leaks.

• Check hydraulic oil level.

• Check hydraulic fittings and hoses.

• Check ram for nicks/damage.

• Check chain roller assembly connections.

• Check for any worn or damaged parts.

Summary of Contents for Stack-N-Go FPS3000-43NAS

Page 20: ...20 Southworth Products FPS3000 43NAS Manual 9 Control Pod 9 1 August 2018 and Prior...

Page 21: ...21 Southworth Products FPS3000 43NAS Manual 9 2 September 2018 to Present...

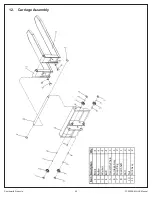

Page 22: ...22 Southworth Products FPS3000 43NAS Manual 10 Steering Assembly 10 1 August 2018 and Prior...

Page 23: ...23 Southworth Products FPS3000 43NAS Manual 10 2 September 2018 to Present...

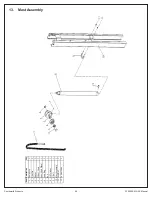

Page 29: ...29 Southworth Products FPS3000 43NAS Manual 16 Hydraulic Schematic...

Page 32: ...32 Southworth Products FPS3000 43NAS Manual...

Page 33: ...33 Southworth Products FPS3000 43NAS Manual 18 2 November 2017 to Present...