TROUBLESHOOTING

-40-

For Machines Mfd. Since 9/20

South Bend Tools

Model SB1092 & SB1094

TROUBLESHOOTING

If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free

to call us at (360) 734-1540.

Machine does not

start or a breaker

trips immediately

after startup.

1.

Dust collector not properly

connected to ducting.

1.

Connect dust collector to ducting (Page 23).

2.

Machine circuit breaker has tripped

(SB1092).

2.

Reset circuit breaker on switch.

3.

Blown fuse.

3.

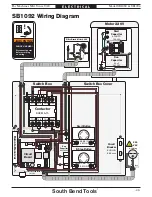

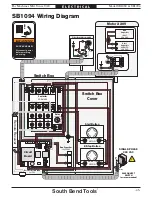

Replace fuse/ensure no shorts (Page 43 & 45).

4.

Incorrect power supply voltage or

circuit size.

4.

Ensure correct power supply voltage and circuit

size.

5.

Remote control not working.

5.

Replace battery; stay in signal range (Page 39).

6.

Remote receiver at fault.

6.

Replace.

7.

Thermal overload relay has tripped/

at fault (SB1094).

7.

Reset. Adjust or replace if at fault.

8.

Power supply circuit breaker

tripped or fuse blown.

8.

Ensure circuit is free of shorts. Reset circuit

breaker or replace fuse.

9.

Motor wires connected incorrectly.

9.

Correct motor wiring connections.

10.

Start capacitor at fault.

10.

Test/replace if at fault.

11.

Wiring broken, disconnected, or

corroded.

11.

Fix broken wires or disconnected/corroded

connections.

12.

Power switch/circuit breaker at fault.

12.

Test/replace.

13.

Centrifugal switch adjustment/

contact points at fault.

13.

Adjust centrifugal switch/clean contact points.

Replace either if at fault.

14.

Motor or motor bearings at fault.

14.

Replace motor.

Machine stalls or is

underpowered.

1.

Dust collection ducting problem.

1.

Allow motor to cool, reset overload if necessary.

2.

Collection bags full.

2.

Replace collection bags.

3.

Canister filter clogged/at fault.

3.

Clean canister filter (Page 36); replace canister

filter after 1 year of regular use (Page 38).

4.

Run capacitor at fault.

4.

Test/repair/replace.

5.

Circuit board at fault.

5.

Replace if at fault.

6.

Dust collector too far from machine

or undersized for dust-collection

system.

6.

Move closer to machine/redesign ducting layout

(Page 23)/upgrade dust collector.

7.

Motor overheated, tripping machine

circuit breaker.

7.

Clean motor/let cool, and reduce workload. Reset

breaker.

8.

Motor or motor bearings at fault.

8.

Test/repair/replace.

9.

Centrifugal switch adjustment/

contact points at fault.

9.

Adjust centrifugal switch/clean contact points.

Replace either if at fault.

Symptom

Possible Cause

Possible Solution

Machine has

excessive vibration

or noise.

1.

Motor or component loose.

1.

Inspect/replace damaged or missing bolts/nuts, and

retighten with thread-locking fluid.

2.

Motor mount loose/broken.

2.

Tighten/replace.

3.

Motor fan rubbing on fan cover.

3.

Fix/replace fan cover; replace loose/damaged fan.

4.

Centrifugal switch is at fault.

4.

Adjust/replace centrifugal switch if available.

5.

Impeller damaged, unbalanced, or loose.

5.

Inspect/tighten/replace.

6.

Motor bearings at fault.

6.

Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.