South Bend Tools

For Machines Mfd. Since 12/21

Model SB1102

-37-

S E R V I C E

Adjusting/Replacing

V-Belts

New V-belts often stretch and loosen up during

the first 16 hours of use. After this period,

they should be inspected and re-tensioned if

necessary. Replace V-belts if you notice fraying,

cracking, glazing, or any other damage. A worn/

damaged belt will not provide optimum power

transfer from the motor to the drums.

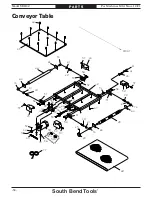

The sanding drums are driven by two V-belts.

The belts must have proper tension for optimum

power transfer. However, too much tension may

cause premature bearing failure. Proper tension

is achieved when the belts deflect about

3

⁄

4

"

with moderate finger pressure at the midpoint

between the drum pulley and the motor pulleys

(see Figure 47).

Items Needed:

• Open-End or Socket Wrench 17mm

• Straightedge (at least 24")

• Tape Measure

• Phillips Screwdriver #2

• Hex Wrench 5mm

• Hex Wrench 3mm

Belt Tension

Figure

Figure 47. Proper V-belt deflection.

. Proper V-belt deflection.

Motor Pulley

Approx.

3

⁄

4

"

Deflection

Drum Pulleys

Always inspect V-belts for damage or

deterioration when adjusting tension. Should

you find evidence of fraying, cracking, or

other damage, replace the belt immediately.

Belt breakage could lead to mechanical

damage or operator injury.

1.

DISCONNECT MACHINE FROM POWER!

2.

Remove handwheel and micro-adjustment

knob.

3.

Open dust hood and disconnect right side

support arm (see Figure 48).

Belts and pulleys will be hot after operation.

Allow them to cool before handling.

4.

Remove (10) machine screws, shown in

Figure 49, from right side panel and

carefully remove panel.

Figure

Figure 48. Dust hood support arm location.

Dust hood support arm location.

Dust Hood

Dust Hood

Support Arm

Support Arm

Adjustment Knob

Adjustment Knob

Set Screw

Set Screw

!

To adjust V-belt tension:

Figure

Figure 49. Right side panel machine screws.

Right side panel machine screws.

x 10