26

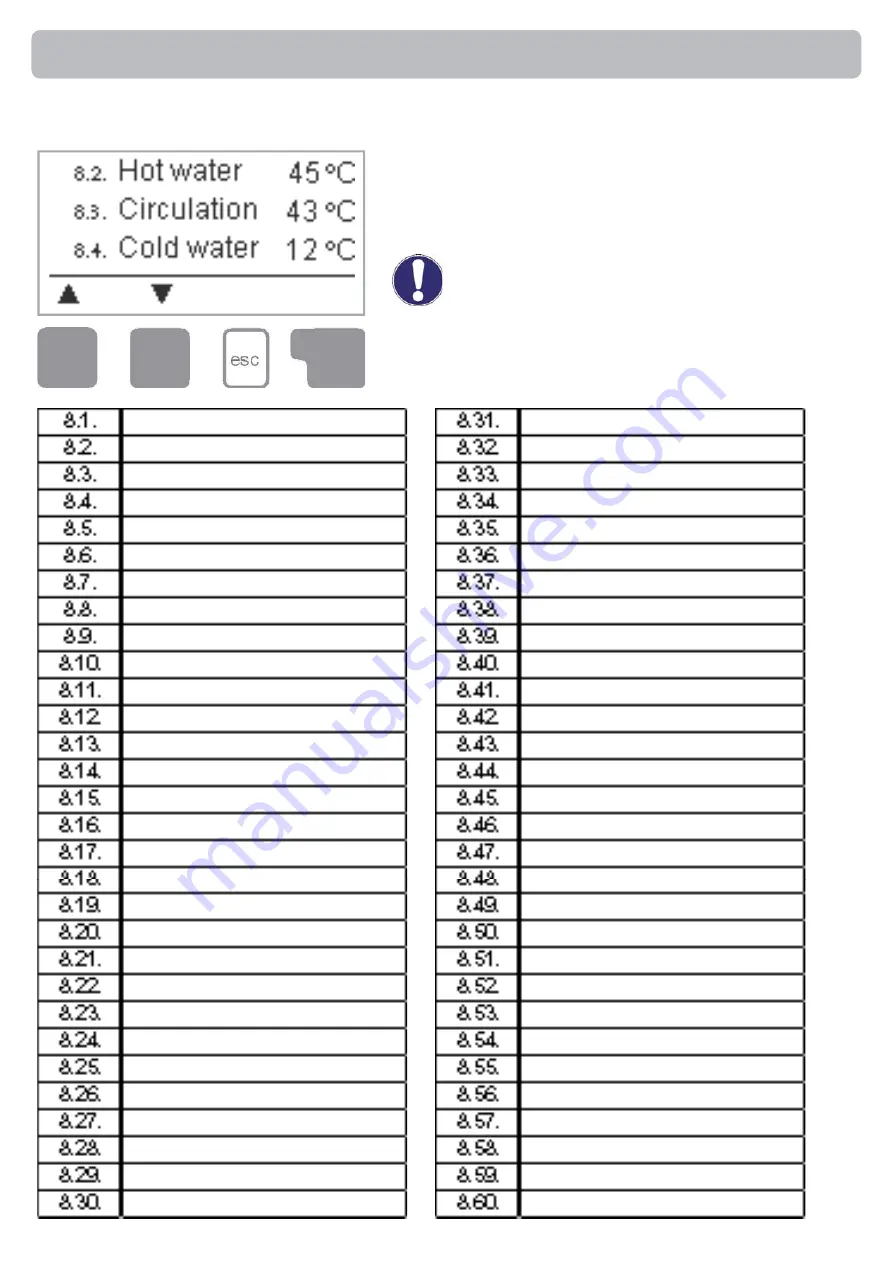

The menu “8. Service values” can be used for remote

diagnosis by a specialist or the manufacturer in the

event of an error, etc.

Caution

Enter the values at the time when the error

occurs e.g. in the table.

The menu can be closed at any time by pressing “esc”.

Service values

8. - Service values