– 22 –

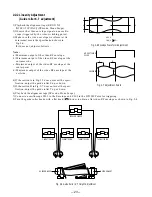

2-2-1(a) ACE HEAD HEIGHT ADJUSTMENT

1) Run the alignment tape (KRV-52NE (NTSC)/52PL

(PAL)) in the playback mode.

2) Observe surface of the audio head using a dental

mirror.

3) Turn screw (C) clockwise or counterclockwise until

the gap of lower tape edge and the lower edge of

the control head is about 0.25mm.

(Refer to Fig. 2-3 and 2-4)

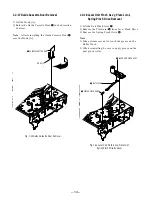

Fig. 2-3 Location of ACE Head Adjustment Screw

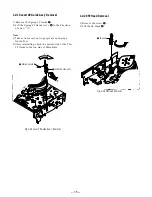

Fig. 2-4 ACE Head Height Adjustment

SCREW (A)

TLIT ADJUST

X-POSITION

ADJUSTING SLIT

SCREW (C)

HEIGHT ADJUST

SCREW (D)

X-POSITION LOCKING

SCREW (B)

AZIMUTH ADJUST

0 ~ 0 .25 mm

AUDIO HEAD

VIDEO HEAD

CONTROL HEAD

2-2-1(b) ACE HEAD TILT ADJUSTMENT

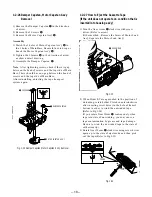

1) Playback a blank tape and observe the position of

the tape at the lower flange of tape guide.

2) Confirm that there is no curl or wrinkle at the

lower flange of tape guide as shown in Fig. 2-5 (B).

3) If a curl or wrinkle of the tape occurs, slightly turn

the screw (A) tilt adjust on the ACE head ass’y.

4) Reconfirm the ACE head height.

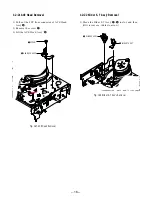

Fig. 2-5 Tape Guide Check

2-2-1(c) AUDIO AZIMUTH ADJUSTMENT

1) Load alignment tape (KRV-52NE (NTSC)/52PL

(PAL)) and playback the NTSC : 5KHz (PAL :

4KHz) signal.

2) Connect channel-1 scope probe to audio output

test point.

3) Adjust screw (B) to achieve maximum audio level.

(See Fig. 2-3)

2-2-1(d) ACE HEAD POSITION (X-POINT)

ADJUSTMENT

1) See “2. Alignment and Adjustment” for ACE Head

position (X-Point) adjustment.

(BAD)

WRINKLE

(GOOD)

2-2 Tape Transport System Adjustment

When parts are replaced, perform the required

adjustments by referring to procedures for the tape

transport system. If there are any changes to the tape

path, first run a T-120 tape and make sure excessive

tape wrinkle does not occur at the tape guides.

1) If tape wrinkle is observed at the guide roller S, T,

turn the guide roller S, T until wrinkle disappears.

2) If the tape wrinkle is still observed at the tape

guide, perform the tilt adjustment of the ACE head.

(See page 5-3 of the Service Manual for Test Point

Locations.)

2-2-1 ACE Head Assembly Adjustment