15

MZ-R701/R701DPC

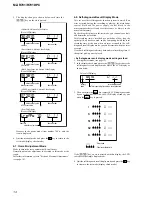

• Description of indication history

History code number

Description

1

The first error

N

The last error

N1

One error before the last

N2

Two errors before the last

R_

Total recording time

4-9. Reset the Error Display Code

After servicing, reset the error display code.

• Setting method of reset the error display code

1. Setting the test mode (see page 12).

2. Press

[ENTER]

key activates the self-diagnosis result display

mode.

3. To reset the error display code, press the

X

key (2 times) when

the code is displayed (except “R_

****

”).

(All the data on the 1, N, N1 and N2 will be reset)

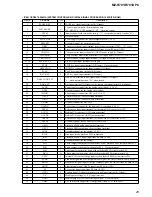

• Description of error indication codes

Problem

Indication code

Meaning of code

Simple display

Description

No error

00

No error

---

No error

01

Illegal access target

Adrs

Attempt to access an abnormal address

address was specified

Servo system error

02

High temperature

Temp

High temperature

03

Focus error

Fcus

Disordered focus

04

Spindle error

Spdl

Abnormal rotation of disc

TOC error

11

TOC error

TOC

Faulty TOC contents

12

Data reading error

Data

Data could not be read at SYNC

Power supply system error

22

Low battery

LBat

Momentary interruption detected

31

Offset error

Ofst

Offset error

32

Focus error

ABCD

Focus error

ABCD offset error

ABCD offset error

Offset system error

33

Tracking error

TE

Tracking error

Offset error

Offset error

34

X1 tracking error

X1TE

X1 tracking error

Offset error

Offset error