© Trynex International 2008 L1186

8 — 29

Troubleshooting

Loose electrical connections.

Blown Fuse.

Motor Seized.

Jammed auger.

Poor electrical connections.

Electrical short.

Controller failure.

Empty hopper.

Wet material.

Frozen or coarse material.

Spinner not turning.

Auger loose on shaft.

Vibrator not working.

Jammed auger, overload shut down.

Short in system.

Motor is not getting power.

Vehicle battery is extremely low,

or a poor connection exists.

Whenever service is necessary, your local SnowEx Dealer knows your Spreader best. Take your Spreader to your local dealer for any

maintenance or service needs on your unit. If this is not possible, the Troubleshooting Guide below may assist you in identifying the problem

Warning:

First read all warning instructions and safety messages before servicing your spreader.

Preliminary Checks

•

Be sure all electrical connections are tight and clean.

•

Be sure nothing is jammed in the hopper.

Motor doesn’t run.

Controller shut down.

Material not flowing

from hopper.

Audible alarm beeping and

display shows OL or OH.

Audible alarm beeping

display shows E1.

Audible alarm beeping

display shows EO.

Audible alarm beeping

display shows LB.

Check all connections.

Replace fuse.

Replace motor.

Carefully clear jammed material.

Clean or replace connectors.

Use dielectric grease.

Check electrical connections.

Check for bare wires.

Replace controller.

Fill hopper.

Replace with dry material.

Replace material.

Check drive assembly.

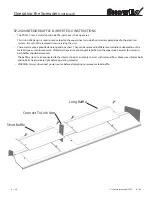

Tighten locking bolt on the side of the auger. There is a flat

machined on the driver shaft. Align the auger with this flat

and tighten the bolt.

Replace vibrator

Turn off for three seconds, then restart. If shut down

continues, turn off controller. Clear debris and lumps from

auger areas.

Turn off. Do not use until problem is corrected.

Turn off. Check all connections.

Turn off. Charge battery.

PROBLEM

POSSIBLE CAUSE

SOLUTION

Summary of Contents for SP-2400

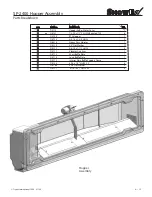

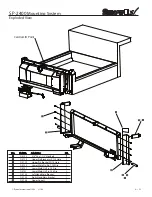

Page 9: ...Trynex International 2008 L1186 8 9 SP 2400 Front and Rear Views...

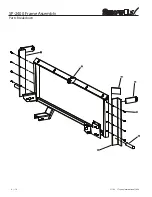

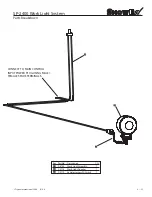

Page 10: ...L1186 Trynex International 2008 8 10 SP 2400 Auger Drive Assembly Parts Breakdown...

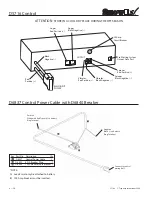

Page 12: ...L1186 Trynex International 2008 8 12 SP 2400 Spinner Drive Assembly Parts Breakdown...

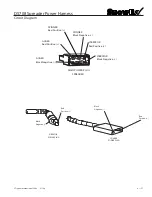

Page 14: ...L1186 Trynex International 2008 8 14 SP 2400 Hopper Assembly Parts Breakdown...

Page 16: ...L1186 Trynex International 2008 8 16 SP 2400 Frame Assembly Parts Breakdown...