11

S

ection

3 — A

SSembly

& S

et

-U

p

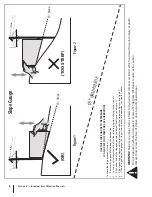

1.

On the side of the mower, lift the side mulching plug. See

Figure 3-9.

2

1

Side Mulching

Plug

Figure 3-9

2.

Slide two hooks of side discharge chute under hinge pin on

mulching plug assembly. Lower the mulching plug. Do not

remove side mulching plug at any time, even when you are

not mulching.

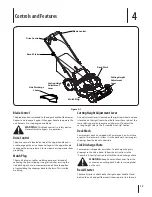

Adjustments

Cutting Height

There is a cutting height adjustment lever located above the

front and rear right wheel.

1.

Pull the height adjustment lever towards wheel (unit will

tend to fall when lever is moved outward).

2.

Move lever to desired position for a change in cutting

height. See Figure 3-10.

3

2

1

2

3

1

Lower

Lower

Higher

Higher

Figure 3-10

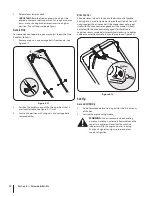

b. Slip plastic channel of grass bag over hooks on the

frame. See Figure 3-7.

B

A

Figure 3-7

2.

Follow steps below to attach grass catcher:

a. Lift rear discharge door.

b. Place grass catcher into the slots in the handle

brackets as shown in Figure 3-8. Let go of discharge

door so that it rests on the grass catcher.

A

B

B

Figure 3-8

To remove grass catcher, lift rear discharge door on the mower.

Lift grass catcher up and of the slots in the handle brackets.

Release rear discharge door to allow it to close rear opening of

mower.

Side Discharge Chute

Your mower is shipped as a mulcher. To convert to side discharge,

make sure grass catcher is off of the unit and rear discharge door

is closed.