24

Regular Maintenance

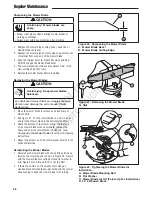

Check / Fill Transmission Oil

Oil Type:

20W-50 conventional detergent motor oil.

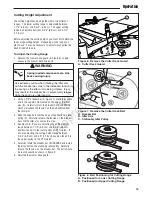

1. Check the oil level when the unit is cold. Locate the

transmission oil reservoirs (A, Figure 15) located on

the by the fuel tank. The oil should be up to the “FULL

COLD” mark (B). If the oil is below this level, proceed

to step 2.

2. Before removing the reservoir caps, make sure the area

around the reservoir cap and fill neck of the reservoir is

free of dust, dirt, or other debris. Remove the reservoir

cap.

3. Add oil up to the “FULL COLD” mark (B).

4. Reinstall the reservoir caps.

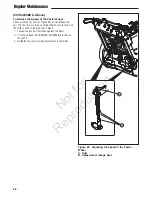

Transmission Oil Filter Change

Change Interval:

Every 200 Hours

Replacement Filter Number:

5101026X1

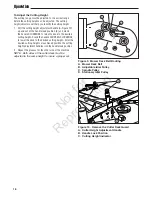

1. Locate the transmission oil filters (A, Figure

16) underneath the rear of the machine on the

transmissions.

2. Remove the three 1/4” filter guard screws (C) and the

filter guard (B).

3. Clean the area around the filter base and remove the

filter.

4. Apply a film of new oil to the gasket of the new

replacement filter. After the oil has drained, thread the

new filter onto the filter base until the gasket makes

contact, then tighten 3/4 of a turn more.

5. Reinstall the filter guard with the three 1/4” filter guard

screws

6. Using a hex bit swivel socket or a modified allen wrench

remove the top port plug from the transmissions.

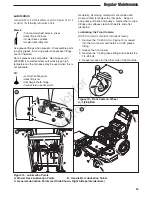

7. Remove the transmission reservoir cap and fill with oil

until oil appears at the bottom of the transmission’s top

port (approximately 2 qts (1,89L).

8. Reinstall the top port plug and tighten to 15 ft lbs (20,38

Nm).

9. Continue to add oil to the transmission oil reservoirs

until the oil level reaches the “FULL COLD” mark.

Reinstall the oil reservoir cap.

10. Repeat this process for the other side of the machine.

11. Run the unit for several minutes and check the

transmission oil level.

IMPORTANT NOTE: Use caution after changing

the filter; air in the hydraulic system may affect the

responsiveness of the ground speed control levers.

Repeat step 11 until the air is out of the system.

Figure 16. Transmission (Left Side Shown.)

A. Transmission Oil Filter

B. Filter Guard

C. 1/4” Filter Guard Screws

D. Top Port Plug

A

B

C

D

Figure 15. Transmission Oil Reservoir (LH Shown)

A. Transmission Oil Reservoir

B. “FULL COLD” Mark

A

B

Not

for

Reproduction