3

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

6. Check the area to be mowed and remove all objects

such as toys, wire, rocks, limbs and other objects

that could cause injury if thrown by blade or

interfere with mowing.

7. Keep people and pets out of mowing area.

Immediately STOP blades, STOP engine, and

STOP machine if anyone enters the area.

8. Check shields, deflectors, switches, blade

controls and other safety devices frequently for

proper operation and location.

9. Make sure all safety decals are clearly legible.

Replace if damaged.

10. Protect yourself when mowing and wear safety

glasses, long pants and substantial footwear.

11. Know how to STOP blades and engine quickly

in preparation for emergencies.

12. Use extra care when loading or unloading the

machine into a trailer or truck.

13. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive

1. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

2. Use only an approved fuel container.

3. DO NOT remove fuel cap or add fuel with the

engine running. Allow the engine to cool before

refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container

inside where there is an open flame, spark or

pilot light such as on a water heater or other

appliances.

6. DO NOT fill fuel containers inside a vehicle or

on a truck or trailer bed with a plastic liner.

Always place the containers on the ground

away from the vehicle before filling.

7. Remove gas-powered equipment from the

vehicle or trailer and refuel it on the ground. If

this is not possible, then refuel equipment

using a portable container, rather than a

gasoline dispenser nozzle.

8. DO NOT start gas powered equipment in

enclosed vehicles or trailers.

9. Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. DO NOT use a nozzle lock-

open device

10. If fuel is spilled on clothing, change clothing

immediately.

11. Never overfill a fuel tank. Replace fuel cap and

tighten securely.

OPERATION

1. Mount and dismount machine from left side.

Keep clear of discharge opening at all times.

2. Start engine from operator's seat, if possible.

Make sure blades are OFF and parking brake is

set.

3. DO NOT leave machine with engine running.

STOP engine, STOP blades, SET brake, and

Remove key before leaving operators position

of any reason.

4. DO NOT operate machine unless properly

seated with feet on feet rests or pedal(s).

5. STOP BLADES and ENGINE and make sure

blades have stopped before removing grass

catcher or unclogging mower to prevent loss of

fingers or hand.

6. Blades must be OFF except when cutting grass.

Set blades in highest position when mowing

over rough ground.

7. Keep hands and feet away from rotating blades

underneath deck. DO NOT place foot on ground

while BLADES are ON or machine is in motion.

8. DO NOT operate machine without entire grass

catcher or guards in place and working. DO

NOT point discharge at people, passing cars,

windows or doors.

9. Slow down before turning.

10. Watch out for traffic when near or crossing

roadways.

11.

STOP engine immediately after striking an

obstruction. Inspect machine and repair damage

before resuming operation.

12. Operate machine only in daylight or with good

artificial light.

13. Move joystick (if equipped) SLOWLY to maintain

control during speed and directional changes.

14. Exercise CAUTION when pulling loads. Limit

loads to those you can safely control and attach

loads to hitch plate as specified with SNAPPER

attachment instructions.

15. On slopes, the weight of the towed equipment

may cause loss of traction and loss of control.

When towing, travel slowly and allow extra

distance to stop.

16. DO NOT operate engine in enclosed areas.

Engine exhaust gases contain carbon

monoxide, a deadly poison.

17. DO NOT discharge material against a wall or

obstruction. Material may ricochet back

towards the operator.

18. Only use accessories approved by the

manufacturer. See manufacturer’s instructions

for proper operation and installation of

accessories.

Summary of Contents for LT180H33 IBV

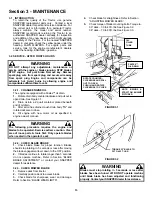

Page 39: ...39 PRIMARY MAINTENANCE...

Page 40: ...40 PRIMARY MAINTENANCE...

Page 41: ...41 PRIMARY MAINTENANCE...

Page 42: ...42 PRIMARY MAINTENANCE...