19

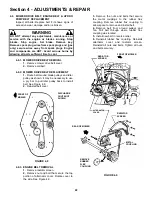

Section 4 - ADJUSTMENTS & REPAIR

DANGER

Exercise EXTREME CAUTION when making this

adjustment, due to close proximity of moving parts.

4.1

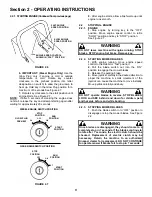

NEUTRAL POSITION ADJUSTMENTS

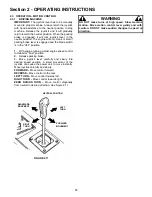

The joystick controls the movement and stopping

of the machine. Move the joystick to the center or

neutral position to stop machine. IMPORTANT:

Always return the joystick with hand assistance to

the neutral position. If machine does not come to a

complete stop or has any movement when joystick

is moved to the neutral position, adjustment must

be made.

1. Turn key to “OFF” position.

2. Raise both wheels off the ground. Wheels

should be high enough to rotate freely. Secure with

safety blocks.

3. Disconnect parking brake rod from parking

brake.

4. Engage parking brake lever. NOTE: Engaging

parking brake without brake rod connected will

lock joystick in center or neutral position.

5. Turn key to start position and start engine.

6. Both wheels should be still, not rotating.

7. If wheel(s) are rotating, disconnect

transmission control rods from cross shaft and

turn adjusting bolts located on pump(s) clockwise,

or counter-clockwise, until wheel(s) stop rotating.

See Figure 4.1.

8. With wheels in neutral, (not rotating) stop

engine and readjust the length of the control rods

until they fit into the cross shaft arms and

reconnect. Tighten securely.

9. Reconnect park brake rod.

10. Start engine. Release park brake. Wheels

should not be rotating if adjusted properly. Repeat

adjustment if necessary.

FIGURE 4.1

4.2

MOWER DECK & COMPONENT ADJUSTMENTS

The following mower deck and component

adjustments and repairs can be made by the owner.

However, if there is difficulty in making these

adjustments and repairs, it is recommended that

these repairs be made by an authorized SNAPPER

dealer.

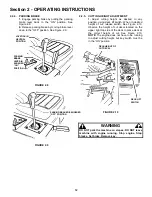

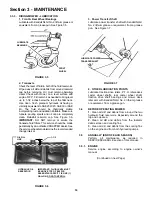

4.2.1. MOWER DECK ADJUSTMENT (LEVELNESS)

SIDE to SIDE and FRONT to REAR

Before making deck leveling adjustments, check

tires and add or release air as needed to bring

pressure to 12 psi in drive tires (Turf Type Tires), 5

psi (All Terrain Type Tires) and 25 psi in rear caster

tires. Pressure in front deck caster wheels should be

25 psi.

If tires are properly inflated and mowing is still

uneven, adjust deck levelness as follows:

1. Place mower on a smooth level surface.

2. Raise deck to highest cutting position.

3. Place 2x4 blocks under front edge of deck beside

caster wheels. Blocks should be on both sides of

deck. Make deck relatively level by positioning

blocks. Both caster wheels must be off the ground.

4. Loosen leveling bracket at center rear deck

support. See Figure 4.2. This allows the lift arm to

settle down into hitch brackets.

FIGURE 4.2

FIGURE 4.1A

LEVELING BRACKET

LOOSEN

NUTS

ADJUSTING BOLTS

TRANSMISSION

CONTROL ROD

TRANSMISSION CONTROL ROD

Summary of Contents for EZF2100DKU, EZF2300GKU, EZF520

Page 30: ...30 NOTES...

Page 31: ...31 NOTES...