73

Accessories

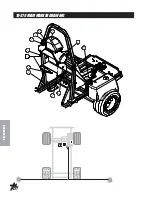

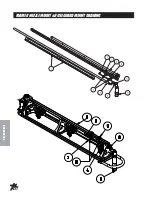

10-417 CHEMICAL CLEANLOAD

®

OPERATING INSTRUCTIONS

STARTUP

1.

All Cleanload valves must be closed prior to starting: inlet ball valve, knife valve and hopper rinse ball valve.

2.

Open lid to check for foreign objects which may hinder performance or contaminate the system.

3.

Close and lock lid by turning cover clockwise.

4.

Divert pump flow to Cleanload inlet line. A pressure of 30 PSI minimum and 150 PSI maximum must be used.

Highest pressures increase eduction rate and available wand suction.

5.

Turn inlet ball valve on (yellow handle).

6.

Open knife valve, located on the bottom of hopper, by pushing handle in (red handle).

7.

Unlock and open lid slowly by turning cover counterclockwise.

LOADING LIQUID OR POWDERED CHEMICAL INTO HOPPER

8.

Pour required amount of chemical into hopper. Avoid splashing liquids or powdered chemicals outside of

hopper.

9.

Rinse empty chemical containers if applicable. Place container opening over container rinse valve and press

down. This will activate the rinse valve and rinse container.

10.

Rinse Cleanload hopper. Close and lock lid by turning cover clockwise. Release the safety locking band on the

hopper rinse ball valve and turn on for 20 seconds. Close ball valve and return locking band to locked position.

11.

Open lid and inspect for chemical residue. Repeat step 10 as necessary.

12.

Close knife valve by pulling red handle out towards you. Turn inlet (yellow handle) off.

LOADING LIQUID AND/OR POWDERED CHEMICAL WITH SUCTION LANCE

Note: Lance suction is dependent upon eductor pressure and flow. For best results, use highest pressure available

up to 150 PSI maximum.

8.

Insert lance body with o-ring into eductor until the o-ring is sealed.

9.

Use the free end of the lance to pierce bag or container to vacuum powdered or liquid chemical.

10.

Rinse lance. Place lance end into a clean container of water to rinse lance assembly.

11.

Remove lance body from eductor and drain any remaining fluid into hopper.

12.

Close knife valve (red handle). Turn inlet valve (yellow handle) off.

SHUTDOWN

1.

Ensure that:

• All valves are closed. Be sure to close knife valve first. (Close by pulling red handle out towards you.)

• Chemical residue has been cleaned.

• Hopper lid is closed and locked by turning cover clockwise.

2.

Divert pump flow back to normal operation.

Symptom

Corrective Action

Check pump pressure and flow. Cleanload Eductor performance is based on

flow and pressure to the system. Note requirements for high eduction rates.

Increase outlet hose size back to tank.

Plugged or clogged bottle rinse nozzle

Disassemble rotary portion of nozzle from lower valve assembly and back

flush until nozzle ports are clear of debris.

Plugged or clogged tank rinse nozzle

Disassemble rotary portion of nozzle from NPT hose barb and back flush until

nozzle ports are clear of debris. Remove screen and flush with water to clear

away foreign material.

Fitting leaks

Check for cracks in fitting. Replace fitting if necessary. Disassemble and add

more joint seal in compound if leak occurs on threads.

Low eduction rate

Summary of Contents for 10-100-C

Page 10: ...8 Service END USER S SERVICE CHART Duplicate this page for routine use...

Page 13: ...NOTES...

Page 14: ...12 Diagrams WIRING DIAGRAM...

Page 16: ...14 Diagrams HYDRAULIC DIAGRAM...

Page 18: ...16 Parts BODY FRAME DRAWING...

Page 20: ...18 Parts NOSECONEDRAWING...

Page 22: ...20 Parts FRONTAXLEDRAWING...

Page 24: ...22 Parts SEATCONSOLEANDROPSDRAWING...

Page 26: ...24 Parts FUELTANKDRAWING...

Page 28: ...26 Parts OILTANK OILFILTER OILCOOLERDRAWING...

Page 30: ...28 Parts FOOTPEDALLINKAGE DRAWING...

Page 32: ...30 Parts ENGINE PUMPSANDEXHAUSTDRAWING...

Page 34: ...32 Parts PARKBRAKEANDREARAXLEDRAWING...

Page 36: ...34 Parts TANKDRAWING TURBO QUADAGITATORDRAWING...

Page 38: ...36 Parts 15 301ORBITROLDRAWING...

Page 40: ...38 Parts 10 117 HYDRAULIC PUMP DRAWING...

Page 42: ...40 Parts 16 998HYPROPUMPDRAWING...

Page 44: ...42 Parts 10 116WHEELMOTOR 14 0 CI DRAWING...

Page 50: ...48 Accessories 16 524 MOTORIZEDCONTROLVALVEDRAWING 15 737STRAINER...

Page 52: ...50 Accessories 17 575 SMITHCOSUPERBOOM...

Page 56: ...54 Accessories 16 906ELECTRICHOSEREELDRAWING...

Page 58: ...56 Accessories 16 129MANUALHOSEREELDRAWING...

Page 60: ...58 Accessories 10 422HOSEREELMOUNT FOR17 525 17 550BOOMS...

Page 62: ...60 Accessories 1008 RAVEN 440 HOSE REEL PLUMBING DRAWING...

Page 66: ...64 Accessories 10 378FOAMMARKERFOR1000DRAWING WIRINGDRAWING...

Page 68: ...66 Accessories 10 378FOAMMARKER DRAWING...

Page 70: ...68 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING...

Page 78: ...76 Accessories 15 620CHEMICALCLEANLOAD DRAWING...