-47-

No. JXC

※

-OMY0008

12. Operation Examples

12.1 Positioning Operation

E.g.) Move an actuator from the origin to 100mm point at 50mm/s. (Step No.1 instruction)

Next, move the actuator from the 50mm point to 100mm point by moving it 5 times continuously,

10mm at a time, at a speed of 50mm/s. (Step No. 2)

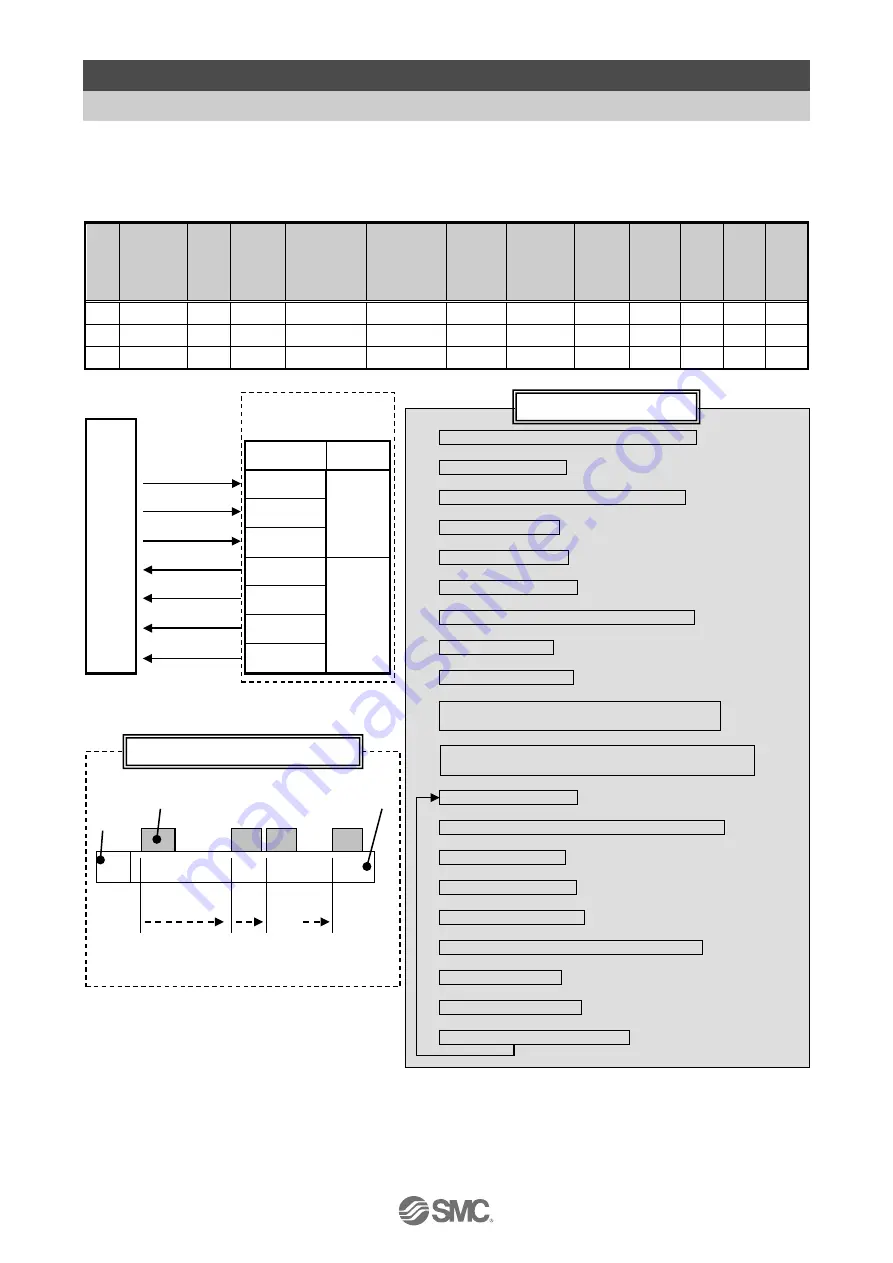

■[Normal mode] Step data

(e.g.)

No.

Movement

mode

Speed

mm/s

Position

(mm)

Acceleration

mm/s

2

Deceleration

mm/s

2

Pushing

force

%

Threshold

Force

Value

%

Pushing

speed

Speed

mm/s

Moving

force

%

Area 1

(mm)

Area 2

(mm)

In pos

(mm)

0

-

-

-

-

-

-

-

-

-

-

-

-

1

Absolute

100

50.00

1000

1000

0

0

0

100

0

0

0, 1

2

Relative

50

10.00

1000

1000

0

0

0

100

0

0

0, 1

(1) Select/input Step No.1. (Turn ON "IN0")

↓

(2) Turn ON "DRIVE"

↓

Start moving to the position of Step No.1.

↓

(3) ”INP” turns OFF.

↓

(4) "BUSY" turns ON.

↓

∗

1

(5) Turn OFF "DRIVE".

↓

(6) Step No.1 is output. ("OUT1" turns ON)

↓

(7) “INP” turns ON.

↓

(8) "BUSY" turns OFF.

↓

The move to the position set in Step Data No.1

is completed.

↓

(9) Select/input Step No.2.

(Turn OFF "IN0" OFF and turn ON "IN1".

↓

(10) Turn ON "DRIVE".

↓

Start moving to 10mm from the current position.

↓

(11) “INP” turns OFF.

↓

(12) "BUSY" turns ON.

↓

*1

(13) Turn OFF "DRIVE".

↓

(14) Step No.2 is output. ("OUT1" turns ON)

↓

(15) “INP” turns ON.

↓

(16) "BUSY" turns OFF.

↓

The 10 mm move is completed.

Actuator

0mm

Origin position

M

Motor

Load

---

100mm

End position

50mm 60mm

・・・

PL

C

(2), (5), (10), (13)

(14), (11), (6), (3)

(16), (12), (8), (4)

(15)

(7)

(9)

(1)

Controller

Signal name Category

DRIVE

Control

signals

IN0

IN1

OUT0

Status

signals

OUT1

INP

BUSY

5 times

∗

1 “SVRE” and ”SETON” must be ON.

(E.g.) Operation

(E.g.) Flow chart