Version 6.00

Date of editing:

16.09.2022

r.

Page 3 z 11

Installation manual

WKP-O

I.

INSTALLATION TECHNOLOGY

–

RIGID WALL

a.

Make an opening in the wall 230 [mm] (acceptable

210 ÷ 250 [mm])

greater than the dimension B and 100 [mm]

(acceptable

80 ÷ 120 [mm])

greater than the dimension H, that is B+230 and H+100.

b.

For the dampers which have height H=200 mm and H=300 mm installation opening should have height H+160

[mm] (acceptable

140÷180 [mm]).

c.

Put the closed fire damper into the installation opening and support or suspend, in this way that the axis of the fire

damper baffle matches the axis of the wall, and ensure a concentricity of fire damper and installation opening. The

damper should be protected against possible undesirable stresses, which could lead to deflection of the housing,

e.g. by using assembly struts.

d.

After setting the fire damper as described, fill the gap between the fire damper and the wall with cement, cement-

lime mortar or concrete.

e.

After drying of the mortar (approx. 48 hours), remove used supports or suspensions, check the fire damper

correct operation and leave it in fully open position.

In order to avoid filling the holes above and below the actuator housing, the opening for the WKP damper can be made

as shown in the figure below.

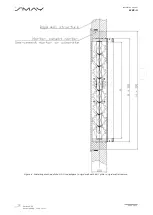

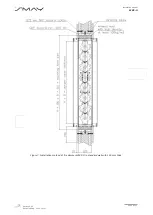

Figure 1. Dimensions of the installation opening of the WKP-O dampers in rigid wall with a horizontal and with vertical

axis of rotation of the baffle, with planned cut for actuator housing. The C dimension is given in the table.

N

C

2

0

3

100

4

100

5

200

6

200

7

300

8

300

N

–

number of blades in damper

Mortar, cement mortar,

cement-lime mortar or concrete

Rigid wall