DC Electric Full-size RTs

December 2007

Page 25

TM

Section 2 - Operation

Visual and Daily Maintenance Inspections

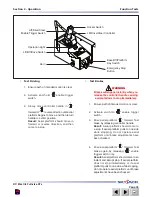

Electrical Panel

Hydraulic Pump/Motor

Assembly

Main Manifold

Brake Manifold

Base Control

Switches

2.8-6 Hydraulic/Electrical Compartment

Ensure all compartment latches are secure

-

and in proper working order.

Electrical Panel

•

Ensure panel is properly secured and

-

there is no visible damage.

Ensure there are no loose wires or

-

missing fasteners.

Manifolds

•

Ensure all fittings and hoses are properly

-

tightened and there is no evidence of

hydraulic leakage.

Ensure there are no loose wires or

-

missing fasteners.

Tilt Sensor

•

Ensure tilt sensor is properly

-

secure and there is no visible

damage.

Base Control Switches

•

Ensure there are no signs of visible

-

damage and all switches are in their

neutral positions.

Emergency Lowering Access Rod

•

Ensure rod is properly secured and there

-

is no visible damage.

Tilt Sensor