8

SKYBLADe FANS

-

Where Form Follows Function

3

MoUNTiNg CoNSiDeRATioNS

3.1 General Mounting

Each type of mounting system requires a specific mounting bracket. Most are available from Skyblade

Fans. Check with the contractor, building owner, or architect to ensure the structure is sound and

will support the weight of the fan before beginning installation. Skyblade Fans provides guidelines for

mounting fans; however, it is the sole responsibility of the building owner and installer to ensure the

safety of the mounting system, that the building structure is sound, and the installation complies with

all federal, state, and local codes.

3.2 Weight

A Standard 1.35-horsepower, Shop Prop Series 12 foot 5-blade fan and mounting assembly weighs

about 114 pounds. In inverted-blade applications designed to blow air upward, there is an additional

downward force of about 80 pounds due to fan thrust. We recommend applying a safety factor of 2

times the stated hanging weight of the fan when determining the capabilities of the building structure.

3.3 Torque

The maximum torque that must be handed by the mounting system and the building structure will

occur at the fans startup. For a 12 foot fan, maximum potential startup torque is 300 ft-lbs. Skyblade

Fans use a soft-start technology which allows the rpm to ramp up as desired over 60 seconds. The

event of this max torque being applied is unlikely and will only apply due to a failure of the variable

frequency drive and its soft start technology.

3.4 Safety Cable

A Skyblade fan should never be run without proper installation of Safety Cables. These are supplied

with every fan. You must install safety cable for warranty to be in effect.

3.5 Guy Wires

While in operation a fan can sway due to minor imbalance or because of wind. Since the mounting

system is capable of swiveling, it will not stop fan movement, so it is important that the guy wires be

installed properly. Proper installation includes the angle and tension of the guy wires. See page 22-23

for more information.

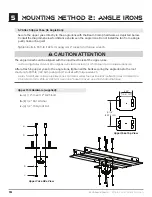

3.6 Universal Mounting Hardware

We recommend mounting the fan to a unistrut or angle iron spanning between trusts, however, this is

not always possible in buildings with pitched roof construction. For this reason, our universal mounting

system is designed to allow the fan to hang in a level position perpendicular to the ground by rotating

the upper yoke 90 degrees.

When cutting or drilling into a wall or ceiling, take care not to damage electrical wiring or other utilities.

Lorsque vous coupez ou percez un mur ou un plafond, prenez garde à ne pas endommager les fils

électriques ou d’autres services publics.

Select a location that is free from obstructions that may interfere with the fan’s operation.

Choisissez un emplacement qui est libre de tout obstacle pouvant interférer avec le fonctionnement

du ventilateur.

CAUTION/ATTENTION

!