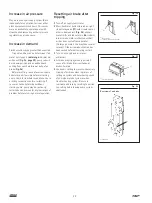

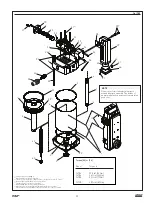

Cylinder tube and

muffler

1

Remove air brakes subassembly

(

Air brake subassembly

,

page 7

)

2

Remove two screws (

30

) and pull off

muffler (

29

)

3

Remove gasket (

28

)

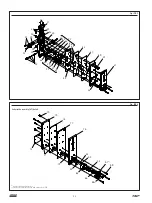

4

Remove four nuts (

26

)

5

Lift upward and remove

upper casting (

8

)

6

Remove four tie rods (

25

)

7

Remove air tube (

7

)

8

Lift upward and remove cylinder tube (

6

)

9

Remove piston and piston rod (

5

)

10

Remove four connecting rods (

41

)

11

Reverse procedure to reassemble

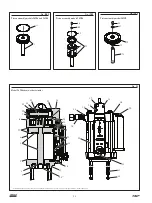

Labyrinth

sub-assembly

re-assembly

procedure

Follow reverse directions of disassembly

procedure with the following precautions to

reassemle labyrinth subassembly:

1

Ensure plastic laminated labyrinth (

77

) is

in good condition before re-assembly

Clear plastic laminate should be in good

condition without any tears or indications

of separation from brass labyrinth plate

inside Inspect labyrinth plate for any signs

of blockage including, but not limited to,

dirt, grease, oil or water that should be

visible through clear laminating material

2

Keep all labyrinth components clean and

free of grease, oil and dirt, except as

noted

3

Very light coating of grease may be used

to retain balls (

79

) in place when installing

selector knob (

84

)

4

Install six screws (

73

) but do not tighten

when reassembling labyrinth sandwich

Install selector knob (

84

) and selector bolt

(

86

) before tightening six screws (

73

)

Tighten six screws (

73

) to 12 in lbf

(1,4 Nm)

Tighten selector bolt (

86

) to

50 in lbf

(5,6 Nm)

5

Use four screws (

80

) and tighten to

12 in lbf

(1,4 Nm)

when installing labyrinth

sub-assembly onto air brake assembly

6

Do not cut or trim clear laminate plastic

from labyrinth assembly

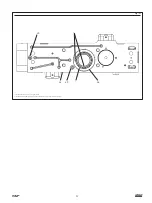

NOTE

Align two holes on cylinder tube (

6

) with two

holes on air brake subassembly before tight-

ening tie rods (

25

) so that proper seal with

o-rings is achieved

8