Form 37714 Rev 1809

Page 3 of 13

Operation

High Flow Applications (1000 to 3000 ml/min)

Set/Calibrate Flow Rate

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Charge battery completely before calibration and sampling.

1.

Ensure that the ba

tt

ery is fully charged and that the pump has run for

fi

ve minutes before

calibrating. Leave the pump running.

2. Prepare the calibrator.

See calibrator instructions

.

3. Set up a calibration train: Using

fl

exible tubing, connect the calibrator outlet (suction port)

to the representative sample medium inlet. Using ¼-inch Tygon tubing, connect the sample

medium outlet to the pump inlet.

See right

.

4.

Using a screwdriver, set the pump

fl

ow rate by turning the

fl

ow adjustment screw on top of the pump

(Figure 1)

,

clockwise

to increase

or

counterclockwise

to decrease

fl

ow, until the calibrator indicates the method-speci

fi

ed

fl

ow rate. Take a minimum of three readings

and record the average

fl

ow rate, as per OSHA/NIOSH instructions.

5. Press the on/o

ff

bu

tt

on to turn o

ff

the pump. Disconnect the calibrator and

fl

exible tubing from the representative sample medium

and proceed to

Set Up/Sample

.

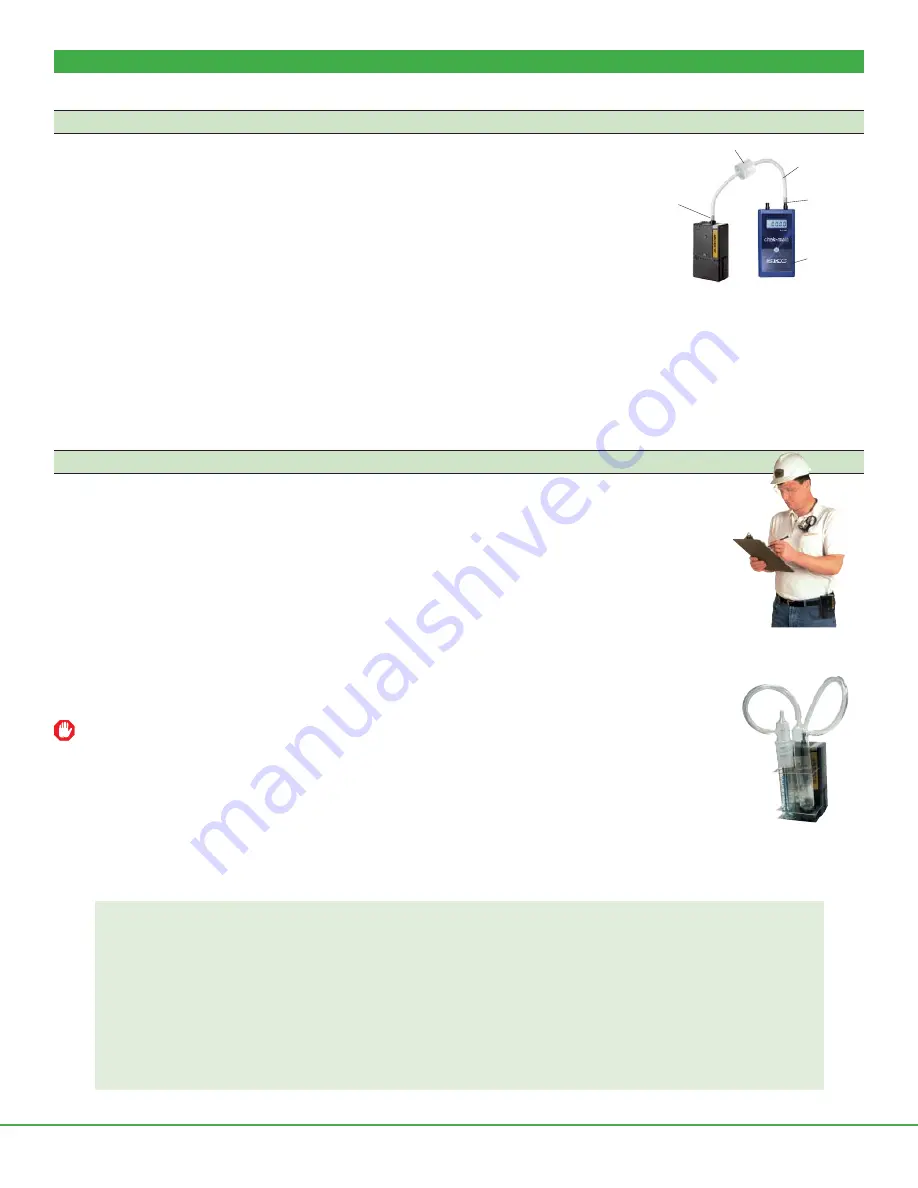

Set Up/Sample

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Protect sample pump from weather when sampling outdoors.

• Powering the pump with any device other than the approved battery pack voids the UL Listing for intrinsic safety.

• Do

not

use the pump with the Battery Eliminator in hazardous locations. UL Listing for intrinsic safety is not in effect

during pump operation with Battery Eliminator.

• Use of any device other than the approved battery pack or Battery Eliminator to power the pump voids any warranty.

• Charge battery completely before calibration and sampling.

1. Replace the representative sample medium with new unexposed medium for sample collection.

2. Place the sample medium where appropriate for sampling.

a. For

personal sampling,

clip the sample collection medium to the worker in the breathing zone and the

pump to the worker’s belt using the belt clip.

When using an impinger, an in-line trap (SKC Cat. No. 225-22 or 225-22-01) is required between the pump and

impinger to prevent fumes from accidentally being drawn into the sampler. Failure to use an appropriate in-line

trap during impinger sampling voids any warranty.

b.

For sampling with an impinger,

mount the single or dual impinger and trap (SKC Cat. No. 225-20-01 or

225-20-02) to the face of the sampler using the accessory mounting screws

(Figure 1)

or place them in a

holster at the worker’s waist.

3. Press the on/o

ff

bu

tt

on to clear the elapsed time displayed on the LCD and to start sampling. Record the

start time and other pertinent information. The LCD will automatically display elapsed pump run time.

See below.

Possible Displays During Sampling

Flow or Ba

tt

ery Fault Shutdown -

If the pump is unable to compensate due to excessive back pressure or a low ba

tt

ery

condition exists, it will shut down and timing functions will pause. The LCD will display either a ba

tt

ery-shaped icon

or a

fl

ow fault icon (

) depending on the cause of the shutdown. Upon

fl

ow fault, the pump will a

tt

empt to restart up

to

fi

ve times. To restart from

fl

ow fault, correct the blockage and press the on/o

ff

bu

tt

on twice.

The elapsed run time

display will reset to 0 when the pump is restarted.

If the ba

tt

ery icon is displayed, recharge the ba

tt

ery before sampling.

Displayed Elapsed Run Time -

Elapsed run time is displayed continuously on the LCD. For elapsed times after 999

minutes, the display still shows elapsed time but alternates between displaying the

fi

rst two digits of the elapsed time

and the last three digits. For example, a pump that has run for 1,440 minutes would display

fi

rst “01” and then “440.”

The display maximum is 99 999, which is 99,999 minutes.

4. At the end of the sampling period, press the on/o

ff

bu

tt

on and record stop time and other pertinent information.

chek-mate

Calibrator

Sample medium

Tygon

tubing

Calibration train with

fi

lter cassette

Pump

inlet

Suction

port

Clip sample medium

to worker and pump

to belt.

Impinger holder on pump

with impinger and trap