9

Flange connections (flanges shall be according ISO 7005)

First screw the pipes into the flanges and then the flanges to the multifunctional control.

Recommended torque for flange retaining screws: 3 Nm.

Caution: check the”0” ring is properly placed in the groove of the flange.

Rp 1/2 connection

Prevent foreign matter from getting into the valve during installation. In particular, check the cleanliness of the

inlet and outlet pipes.

The connection must be made using gas pipes with Rp 1/2 ISO 7 thread. Torque: 25 Nm.

Connection to the pilot burner (versions with pilot burner outlet)

4 mm, 6 mm or 1/4'' pipes can be used. Use appropriately sized nut and olive. Tighten to 7 Nm torque

.

WARNING

:

if you don’t use a pilot outlet provided device, you must seal it using optional code no. 0.972.041

Torque: 7 Nm.

ELECTRICAL CONNECTIONS

General precautions

All electrical connections must be made in accordance with current electrical standards. Check that the voltage and

frequency of the coils, given on the valve, are correct. Disconnect the power supply before starting installation.

Check that all connections, in particular the earth, are made properly.

To make this effective you have to use fast-on contact on the body, or a female contact of the connector with correct

characteristic (see EN 60730).

When you use connector, ensure that the fastening screws are never slack.

Automatic valves are powered with a male contact 3003 molex compatible, suitable for female Molex series 3001.

Electrical modulator is powered with a male fast-on connector 2.8 x 0.8 mm.

The 24 Vac versions must be powered by means of an insulating transformer (with very low safety voltage in

accordance with EN 60742). To connect, use AMP 1.1 x 1.1.

Make the connections as specified in the technical instructions for the flame failure device used and/or in the specific

standards for the appliance. The electrical safety cut-off devices (for example, the flame failure device, thermostat

etc.) must cut off the power supply to both solenoid valves simultaneously.

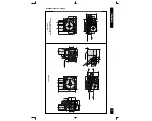

WIRING DIAGRAM

Pin

Po

Ve

P.R.A D J

.

1 2

3 4

EV1

EV2

ENGLISH