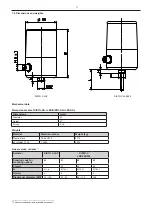

8.2 Mounting of the actual-position feedback unit on the valve actuators of the SISTO-C LAP.520/.530 type series:

8.3 Accessories

13

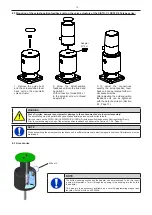

1. Remove the guide bush

and the actual-position feed-

back unit on the pneumatic

valve actuator.

2. Screw the actual-position

feedback unit into the tread and

hand-tight.

With connection thread M18 x 1

in the actuator screw in thread

adapter first.

3. To adjust the connections

exactly, the actual-position feed-

back unit can be rotated further in

clockwise direction.

After adjusting the actual-position

feedback unit can be tightened

with the help of a wire pin (Section

8.3, Page 13).

WARNING

Risk of injuries, damage to equipment or damage to the environment due to incorrect assembly!

The assembling must be performed by qualified specialist personnel with suitable tools.

Carry out work on the SISTO-SK-i LED/SISTO-SK-i LED AS-i actual-position feedback unit during standstill only.

Prior to commissioning/start-up of the actual-position feedback unit observe the Section 9.1-9.4, Page 16.

Adapter

M18 x 1

NOTE

When assembling the actual-position feedback unit, a sufficient distance to electromagnetic sources of interference must be

maintained.

Wire pin

NOTE

The bottom housing section and the adapter can be interlocked. To do this, insert

a wire pin (diameter ≈ 1 mm) through the opening in the housing into the hole in

the adapter.

This wire pin is an accessory available as a set with programming magnet and

lanyard with the article no. 42493506.