MC1000e-R / T

www.siskiyou.com

siskiyou

1-877-313-6418

4

User’s Manual

3.0 Installation

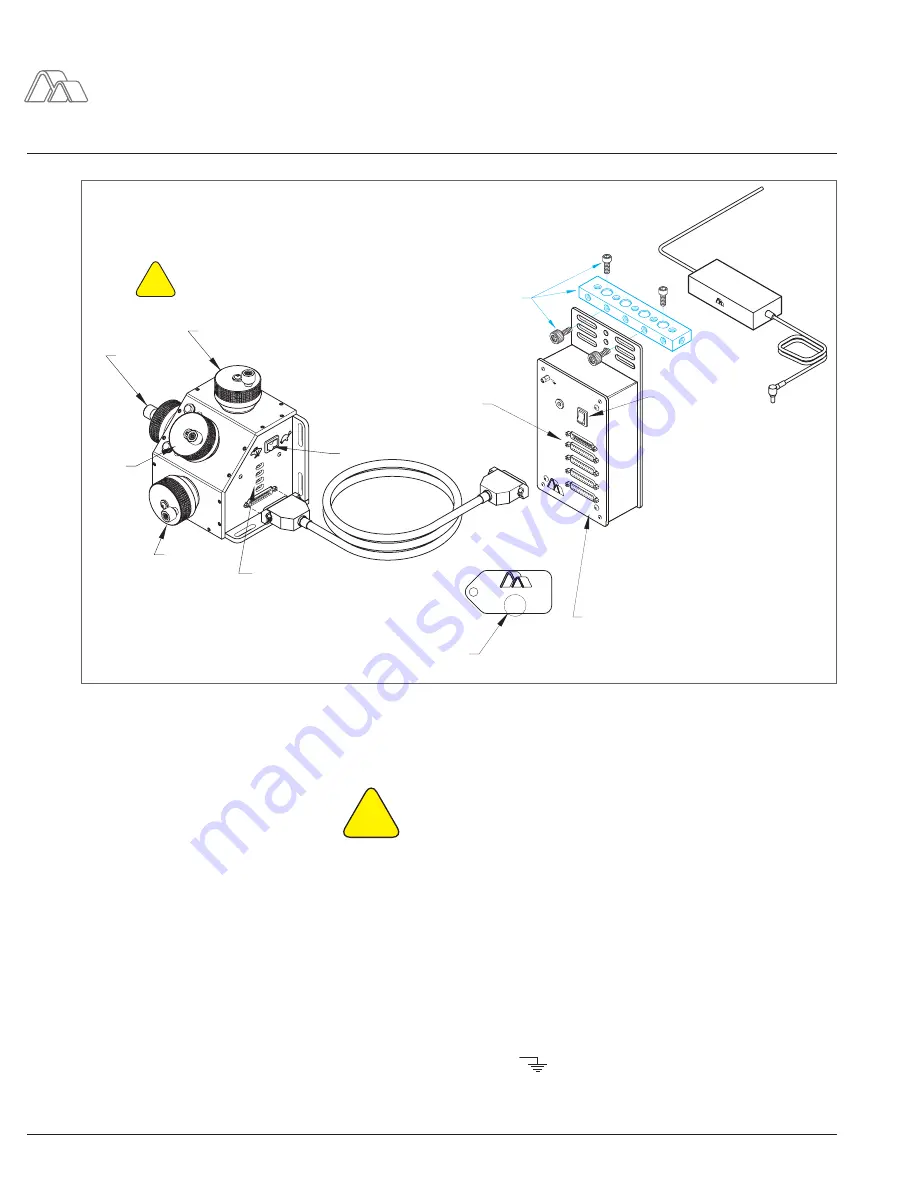

CAUTION: MAKE SURE ALL CONNECTORS ARE SECURELY PLUGGED

IN BEFORE POWER IS TURNED ON. DO NOT REMOVE CONNECTORS

WHILE POWER IS ON. FAILURE TO DO SO CAN RESULT IN A SHORT

CIRCUIT AND PERMANENT DAMAGE TO THE SYSTEM.

To install the MC1000e-R/T, please refer to Figure 1: Interface or the supplied

set up instructions. Supplied with the MC1000e-R/T are two ¼-20 screws that

can be used in securing both the controller and the junction box to the work

station.

It is advised to align Drive Axis No.3 of the controller towards the user. In doing

so, Drive Axis No. 1, 2, 3 and 4 are aligned respectively with the tilt, X, Y, and

Z axes. Each axis is label on the controller by a number. It is also advised to

add a ground wire onto the junction box and attach the free end of the wire to a

metal surface outside of the system. The lug to use is labeled by the electrical

symbol for “ground”:

!

*

1524-76:1-15/8

siskiyou

POWER ON

POWER IN

1

2

3

4

1

2

3

4

MC1000e-R/T CONTR

OLLER

(COMP

ATIBLE

WITH 76:1 GE

ARHEAD)

CONTR

OLLER

BB-5.0 construction

rail and hardware

used for mounting

control and junction

boxes, if needed.

4 screws provided,

BB-5.0 purchased

separately.

Low / High speed switch

Drive axis no.4

Drive axis no.2

Drive axis

no.1

Drive axis no.3

IMPORTANT: Make sure all

connectors are securely

plugged in before power

is turned on.

!

The motor/gearhead ID tag on

each motorized drive and

motorized stage shows the

gearhead ratio. See example:

Reverse polarity switches,

4 places

Power

switch

25 pin D connector

for motorized drive,

4 places

The junction box lid has been

marked to indicate the correct

motor/gearhead type to be

used with this controller.

MC1000e-R / T Setup Instructions

Figure 1: Interface

2

7021000s.eps

POWER AD

APTER