22

MAINTENANCE INSTRUCTIONS….cont

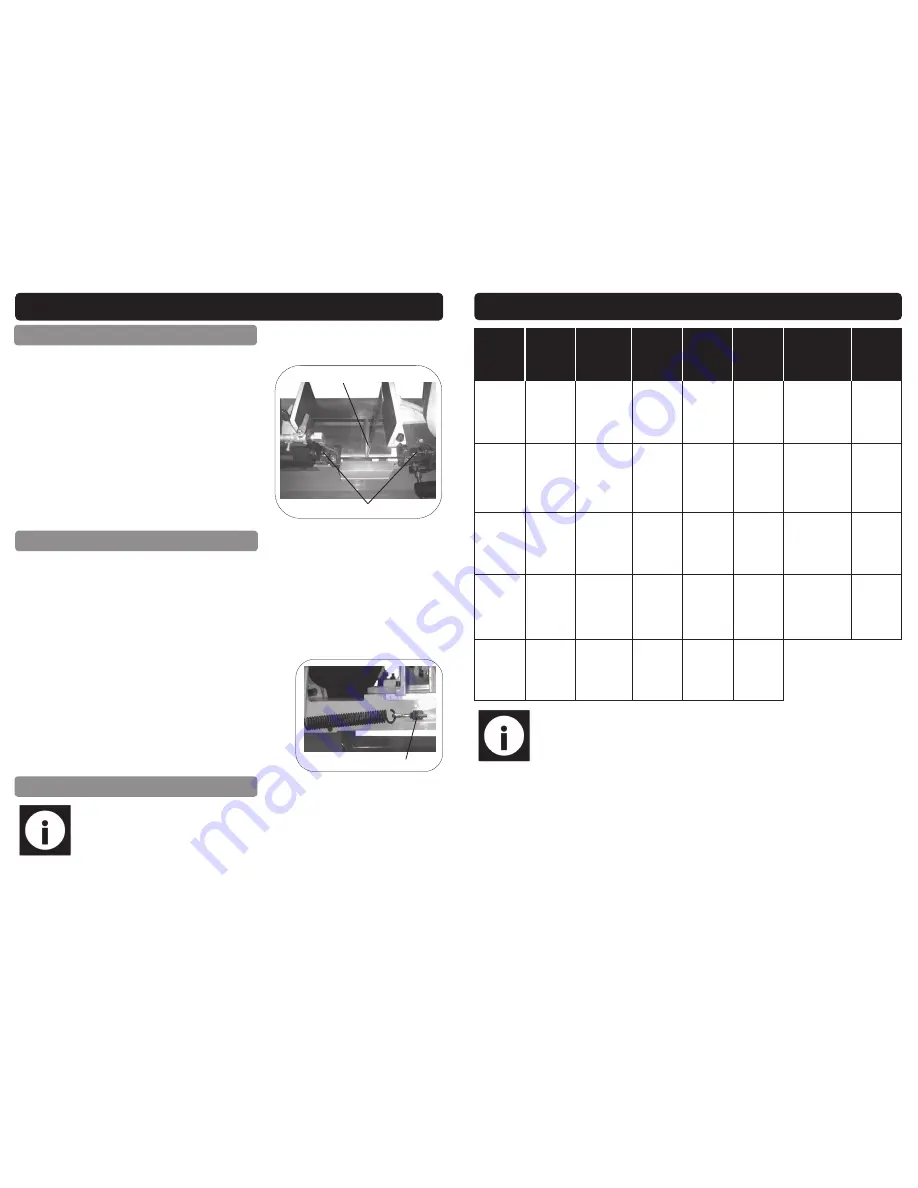

SETTING THE BLADE SQUARE TO THE BED AT 90

˚

1.Ensure the bow is at its lowest position.

2.Disconnect from the mains supply.

3.Place an engineer`s set square onto the bed

and touching the blade (Fig.12).

4.If any adjustment is needed then loosen the two

cap head bolts (Fig.12,A).

5.Rotate both blade guides in the required direc-

tion until the blade makes contact with the set

square along the entire width of the blade.

6.Once set correctly, re-tighten both cap head

bolts.

7.The blade guide bearings may need to adjusted.

Fig.12

A

Set square

Note:

The correct guide bearing adjustment is very important, this will

make the blade run smoother and evenly without any snagging or twisting

whilst the blade is running. It will also prolong the blade life.

BLADE GUIDE BEARING ADJUSTMENT

The bow weight is one of the most important adjustments on the saw. If the bow

weight is set incorrectly then expect poor performance, crooked cuts, teeth stripping

from the blade, stalling and the blade coming off the blade pulleys. The hydraulic

cylinder feed rate will not compensate for improper bow weight. A new machine will

have the bow weight pre-set, if you need to adjust the bow weight then follow the

steps below.

1.Disconnect the mains from the supply.

2.Ensure the bow is at its lowest position.

3.Turn the hydraulic cylinder knob anti-clockwise until it

stops.

4.Place a scale on the Blade tensioning knob, lift the

saw bow up, the scale should read between 5-6kgs.

5.If it doesn't then adjust the tension nut (Fig.7,A) until it

reaches between 5-6kgs.

A

Fig.7

ADJUSTING THE BOW WEIGHT

15

OPERATING INSTRUCTIONS….cont

Material

Speed

M/Min

(FPM)

Material

Speed

M/Min

(FPM)

Material

Speed

M/Min

(FPM)

Material

Speed

M/Min

(FPM)

Carbon

steel

60 - 108

(196 - 354)

Tool steel

62

(203)

Alloy steel

34 - 98

(111 - 321)

Free

machining

stainless steel

46 - 62

(150 - 203)

Steel

section

54 - 67

(180 - 220)

High speed

tool steel

23 - 36

(75 - 118)

Mold steel

75

(246)

Gray cast iron

33 - 75

(108 - 255)

Thin tube

54 - 67

(180 - 220)

Cold work

tool steel

95 - 213

(29 - 65)

Water

hard

tool steel

242

(74)

Ductile

austenitic cast

iron

65 - 85

(20 - 26)

Aluminium

alloy

67 - 163

(220 - 534)

Hot work

tool steel

62

(203)

Stainless

steel

26

(85)

Malleable cast

iron

98

(321)

Copper

alloy

70 - 147

(229 - 482)

Oil

hardening

tool steel

62 - 65

(203 - 213

Cold

rolled

stainless

Steel

26 - 62

(85 - 203)

Note:

The above table is an approximate guide reference only, various

factors mean some materials may require different speeds to the ones

quoted.