9

The panel-mounted printer requires very little maintenance and service. This section provides

instructions for cleaning and maintenance. Electrical and mechanical repairs should be performed

only by qualified personnel.

Make certain all electrical connections are disconnected before any service is performed on

the panel-mounted printer.

•

Voltmeter

•

Denatured alcohol

•

Cleaning cloths

•

Cotton swabs

•

Lubricant (IBM #23, Lubriplate #70, Silicon #35)

You may clean the exterior cabinet of the printer with a non-abrasive cleanser. Do not allow

liquids to enter the inside of the mechanical assembly. In a dirty environment, you may clean the

printhead with alcohol and a cotton swab. You may also use compressed air to clean the printhead.

Do not direct air flow directly to the printer platen; this action may damage the printing surface on

the platen. When the printhead is clean and free of dirt, you may apply a light silicon lubricant

(sparingly) to the moving mechanical components.

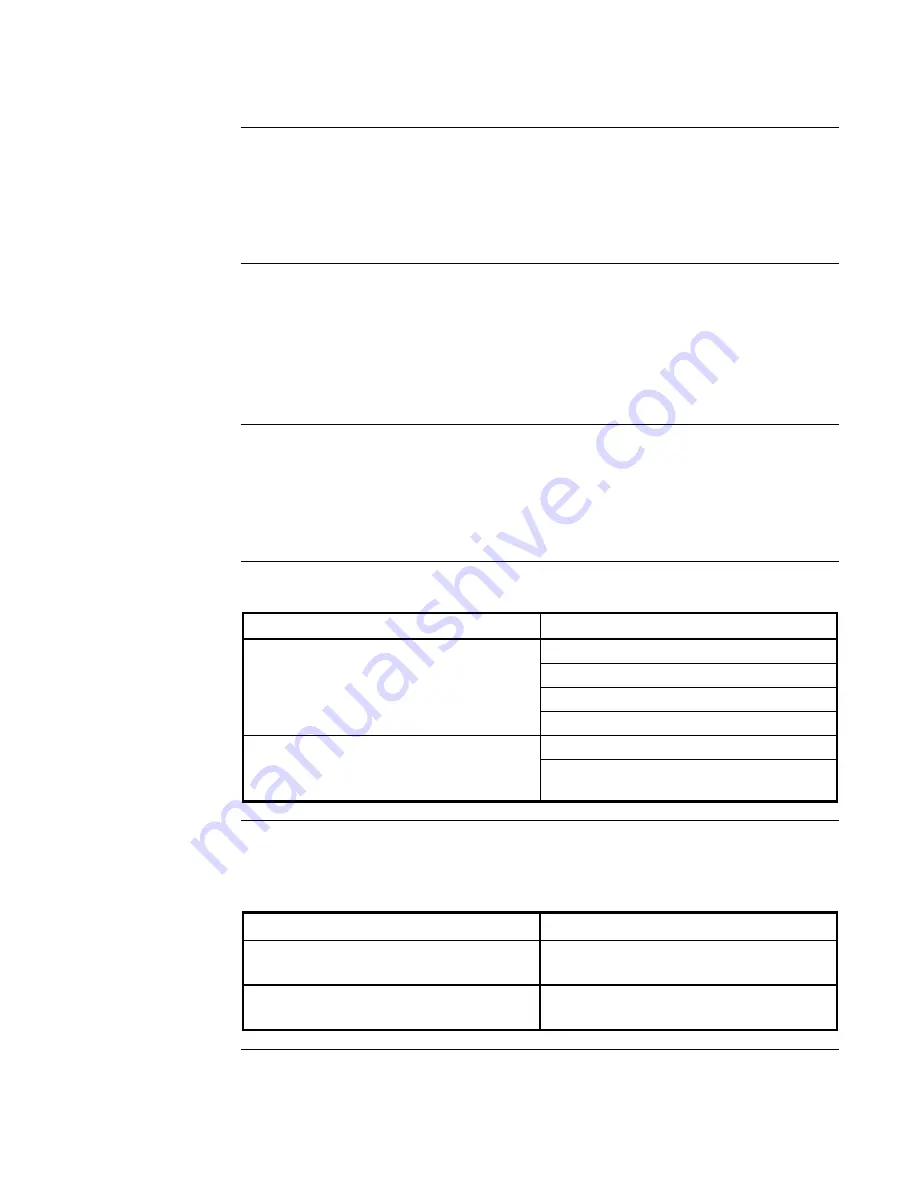

Table 3. Print Problems

Problem Possible

Cause

Poor Print Quality

Dirty thermal printhead

Worn printhead

Poor quality thermal paper

Damaged thermal

Premature Wear of Thermal Printhead

Printing with non-Simplex approved paper

Printing in an environment where abrasive

particles enter the printhead

The following chart is a recommended maintenance schedule for the panel-mounted printer.

Specific environmental conditions may shorten or lengthen the periods between cleaning.

Table 4. Periodic Maintenance Schedule

Clean Office or Light Use

Once Per Year

Clean Factory Environment or

Medium Use

Monthly

Dirty Factory Environment or

Heavy Use

Weekly

Maintenance

Overview

Required Tools and

Supplies

Cleaning

Printing Problems

Maintenance Chart

firealarmresources.com