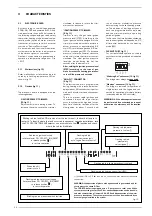

VENTILATION REQUIREMENTS

60 BFR

boiler, installed as class C device

only. Detailled recommendations for air sup-

ply are given in BS5440:2. The following

notes are for general guidance:

– It is not necessary to have a purpose

provided air vent in the room or com-

par tment in which t he appliance is

installed. However, suitable clearances

for maintenance and servicing should be

provided, see fig. 1.

Ventilation requirements for 100 BFR boi-

lers and cascade systems

.

BS6644:2005 has a requirement that the

temperatures in a room or compartment

do not exceed certain levels:

– 25°C at floor level (0-100 mm)

– 32°C at mid level (1.5 M above the floor

level)

– 40°C at ceiling level (0-100 mm from

ceiling)

The following is provide for your guidance

only, and assumes the ventilation air is

taken directly from outside. The sizes of the

vents may need to be increased in respect

of other appliances installed in the same

area, and seasonal use. Take care that the

position of low level vents would not subject

to adverse weather conditions, ie flooding.

When installed as a class B appliance

(open flued, not roomed sealed).

Installed in a room

High level (within 15% of the room height

from ceiling) - 2 cm

2

/KW of net heat input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 4

cm

2

/KW of net heat input. Therefore a sin-

gle

60 BFR

(58 KW net input) boiler would

require 116 cm

2

at high level and 232 cm

2

at low level. A single

100 BFR

(98 KW net

input) boiler would require 196 cm

2

at high

level and 392 cm

2

at low level.

Installed in a compartment or enclosure

High level (within 15% of the room height

from ceiling) - 5 cm

2

/KW of net heat input.

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG) – 10

cm

2

/KW of net heat input.

Therefore a single

60 BFR

(58 KW net

input) boiler would require 290 cm

2

at high

level and 580 cm

2

at low level.

A single

100 BFR

(98 KW net input) boiler

would require 490 cm

2

at high level and

980 cm

2

at low level.

When installed as a class C appliance

(room sealed)

Installed in a room

High level (within 15% of the room height

from ceiling) - 2 cm

2

/KW of net heat input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 2

cm

2

/KW of net heat input

Therefore a single

60 BFR

(58 KW net

input) boiler would require 116 cm

2

at high

level and 116 cm

2

at low level.

A single

100 BFR

(98 KW net input) boiler

would require 196 cm

2

at high level and

196 cm

2

at low level.

Installed in a compartment or enclosure

High level (within 15% of the room height

from ceiling) - 5 cm

2

/KW of net heat input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 5

cm

2

/KW of net heat input.

Therefore a single

60 BFR

(58 KW net

input) boiler would require 290 cm

2

at high

level and 290 cm

2

at low level.

A single

100 BFR

(98 KW net input) boiler

would require 490 cm

2

at high level and

490 cm

2

at low level.

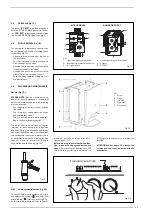

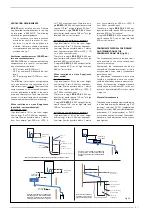

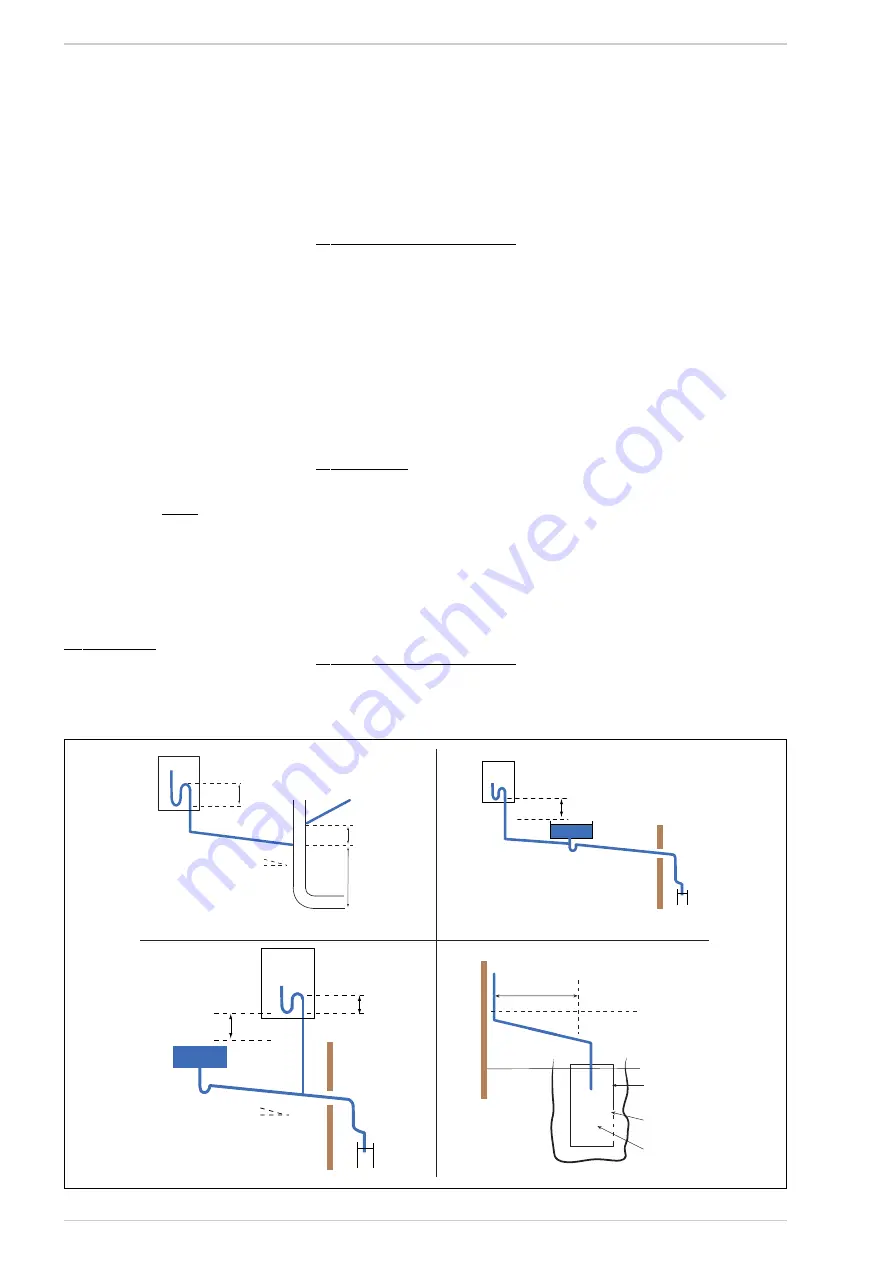

CONDENSATE DISPOSAL POSITIONING

AND TERMINATION OF THE

CONDENSATE DRAIN PIPE (fig. 22)

The condensate pipe should run and termi-

nate internally to the house soil and vent

stack or waste pipe.

Alternatively, the condensate can be dis-

charged into the rainwater system, or into a

purpose-made soak away (condensate

absorption point).

An alternative condensate waste pipe

should be considered where the system

could be effected by extreme weather con-

ditions. All connecting drainage pipework

should have a fall of at least 2.5° to the hor-

izontal, or approximately 50 mm per metre

of pipe run.

Material for condensate

The condensate drainage pipe should be run

in a standard drain pipe material, e.g. PVC

(polyvinyl chloride), PVC-U (unplasticised

polyvinyl chloride), ABS (acrylonitrile-butadi-

enestyrene), PP (polypropylene) or PVC-C

(crosslinked polyvinyl chloride). The conden-

sate drain can be attached to the syphon

(see figures).

31

Pipe slope

>2

1

/

2

deg

Internal trap

>75mm

>110mm

(for 100mm stack)

> 450mm

(for up to 3 floors)

100mm Internal stack

Branch

pipe

SINK

Height above

sink >100mm

Internal trap

>75mm

Pipe slope

>2

1

/

2

deg

Height above

sink >100mm

SINK

> 1m

Section of plastic

drain pipe

Holes in side away

from dwelling

Ground level

Alternative

ground level

Limestone

chipping fill

Internal termination of condensate drainage pipe to internal stack

External termination of condensate

drainage pipe via internal discharge

branch (e.g. sink waste) and condensate

syphon

External termination of condensate

drainage pipe via internal discharge

branch (e.g. sink waste - proprietary

fitting) and condensate syphon

External termination of

condensate drainage

pipe to absorpion point

Fig. 22

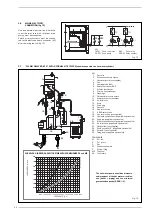

Summary of Contents for Planet Dewy 100 BFR

Page 3: ......

Page 29: ...29 For 100 BFR and boilers in cascade ...

Page 30: ...30 ...

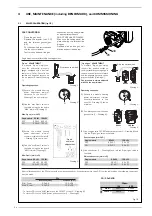

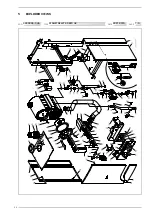

Page 32: ...32 5 EXPLODED VIEWS COD TYPE DATE PAGE 3830005 345 PLANET DEWY 60 BFR UK 20 01 2010 1 4 ...

Page 33: ...33 COD TYPE DATE PAGE 3830005 345 PLANET DEWY 60 BFR UK 20 01 2010 2 4 ...

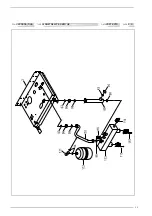

Page 36: ...36 COD TYPE DATE PAGE 3830037 212 Planet Dewy 100 BFR UK 20 01 2010 1 4 ...

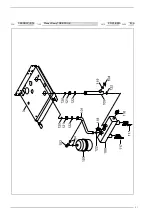

Page 37: ...37 COD TYPE DATE PAGE 3830037 212 Planet Dewy 100 BFR UK 20 01 2010 2 4 ...