Supplied By www.heating spares.co Tel. 0161 620 6677

SIME SUPPORT THE BENCHMARK INITIATIVE

All relevant sections of the logbook must be filled in at the

time of installation and thereafter service information on the

back page of the logbook. Commissioning of the boiler is not

complete until the logbook is filled in.

Before commissioning the appliance, the whole gas installa-

tion including the meter MUST be purged and tested for gas

soundness in accordance with BS6891.

IMPORTANT: open all doors and windows, extinguish naked

lights, and DO NOT SMOKE whilst purging the gas line.

Before commencing the commissioning procedure, ensure

that the gas service cock is turned on, the electricity sup-

ply is isolated, and that the D.H.W. and C.H. isolation valves

are in the closed position.

4.1

FILLING THE WATER SYSTEM

– Open the C.H. flow and C.H. return valves (19 - 18 fig. 2).

– Loosen the automatic air vent cap (9 fig. 2).

– Open all radiator valves and system air vents. Fill the sys-

tem with water using one of the approved methods

described in section 2.9 to about 0.5 bar greater than

the system design pressure. Close all air vents. Do not

close the A.A.V. the one near the pump!

– Check the system for water soundness.

– Completely drain the appliance and heating system, thorough-

ly flush the system, and refill the system design pressure.

– Open the D.H.W. inlet valve, open any hot tap, clear of air

bubbles. Close hot tap.

4.2

COMMISSIONING THE BOILER

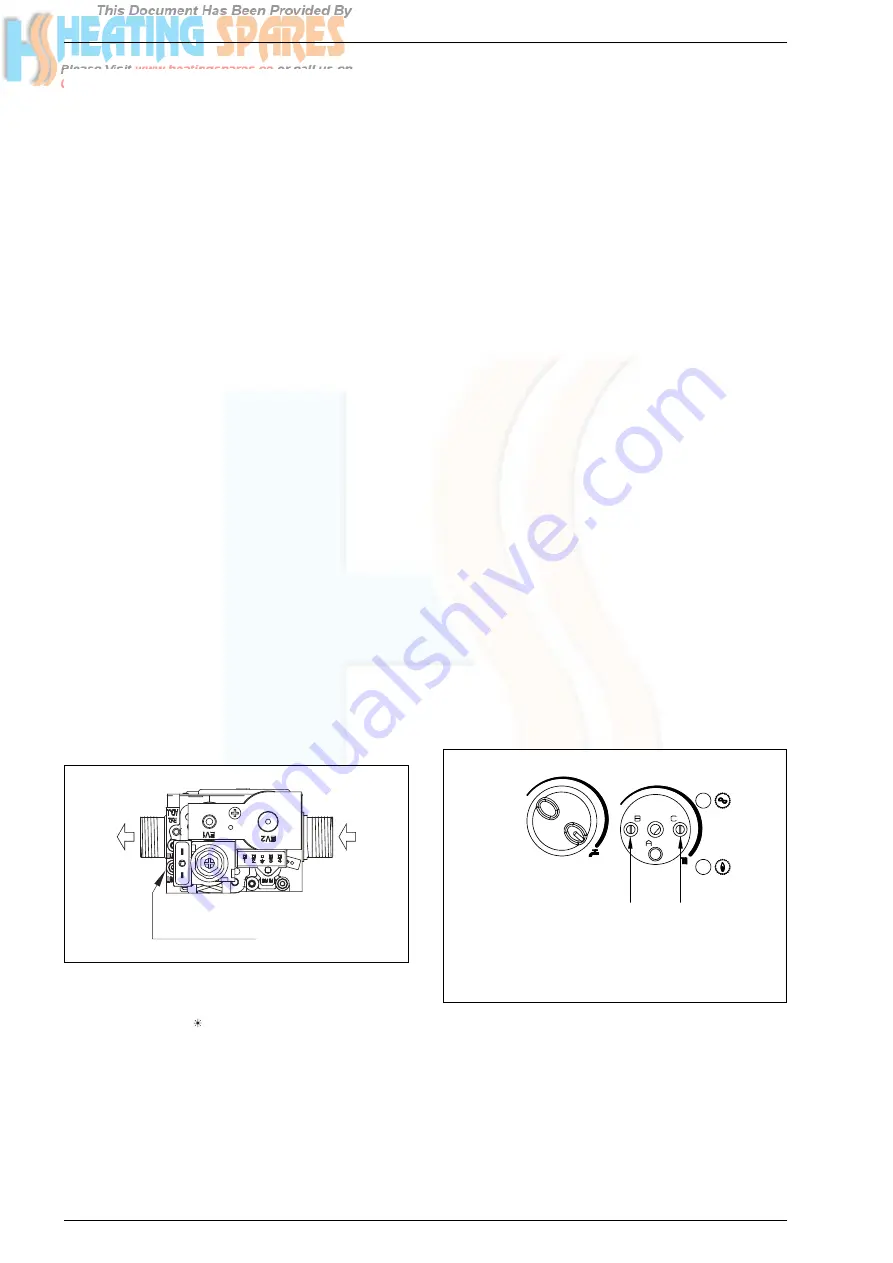

– Remove the screw and connect a pressure gauge to the

burner pressure test point on the gas valve (fig. 21).

– Ensure that the rotary switch on the facia panel is set to the

SUMMER position “

” (D.H.W. Only), turn the D.H.W. ther-

mostat to maximum (fully clockwise), and turn on the electri-

cal supply. Fully open any D.H.W. tap and the burner will light.

– Allow the boiler to run for at least 5 minutes and check

that the burner pressure is as stated in section 1.3. The

D.H.W. burner pressure is factory set and should not

require adjusting. If the burner pressure is low, check that

the appliance has not begun to modulate (this will occur if

the D.H.W. flow rate is low. If modulation is suspected, open

all D.H.W. taps to maximise flow and recheck burner pres-

sure). Check also the inlet pressure with the burner alight;

this should be 20 mbar +/– 1.0 mbar standing pressure

& the working inlet pressure limited to a loss no greater

than 1.0 mbar for natural gas. If it is necessary to adjust

the D.H.W. burner pressure the method is described in

section 8.6.

– Reduce the D.H.W. draw off rate to the minimum neces-

sary to maintain the burner alight by carefully adjusting

the D.H.W. inlet valve and check that the burner pressure

decreases in response to D.H.W. temperature rise. Fully

open the inlet valve.

– Close the D.H.W. tap and ensure that the burner is extin-

guished and the pump stops.

4.3

SETTING THE C.H. INPUT

– Turn the rotary switch to the WINTER position “

❄

" and

ensure that the room thermostat (if fitted) is calling for

heat. Turn the C.H. thermostat knob to maximum (fully

clockwise) and the burner will light.

– Allow the boiler to run for at least 5 minutes and check

the burner pressure. The heating input is factory set as

stated in

Table 3.

– If the heating output is to be adjusted, proceed as follows:

– refer to section 1.3 and establish the desired burner

pressure;

– remove (pull forwards) the C.H. knob protecting the

potentiometer;

– set the burner pressure as required using a small

screwdriver on potentiometer (1 fig. 22). Rotate the

screw anti-clockwise to reduce the burner pressure;

– operate the rotary switch between SUMMER and WIN-

TER position a few times and check that the correct

burner pressure is maintained.

– Replace the C.H. knob over potentiometer.

– To set the time clock see the user instructions.

4.3.1

Ignition gas pressure trimmer (6 fig. 22)

Trimmer to vary the pressure level upon ignition (STEP), of

the gas valve.

According to the type of gas for which the boiler is equip-

ped, the trimmer must be regulated so as to obtain a

pressure of approx. 3 mbar at the burner for methane gas

and 7 mbar for butane gas (G30) and propane gas (G31).

To increase pressure, turn the trimmer clockwise; to redu-

ce pressure, turn the trimmer counterclockwise.

15

4

COMMISSIONING AND TESTING

BURNER PRESSURE

TEST POINT

Fig. 21

1

6

KEY

1 “Heating output” trimmer

6 “Ignition pressure” trimmer

NOTE: To gain access to trimmers (1) and (6), take

off the central heating potentiometer knob.

Fig. 22