67

IT

ES

ENG

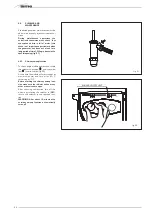

such as

Sentinel X100 or Fernox Protec-

tor F1

is recommended after cleaning the

system. It is important to check the con-

centration of the inhibit or af t er each

system modification and during maintenan-

ce following the manufacturer’s instruc-

tions (specific tests are available at your

dealer). The safety valve drain must be con-

nected to a collection funnel to collect any

discharge during interventions.

WARNING: Failure to clean the heat

system or add an adequate inhibitor inva-

lidates the device’s warranty.

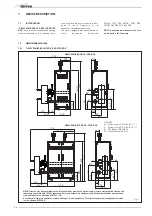

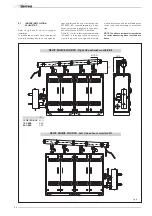

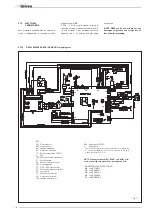

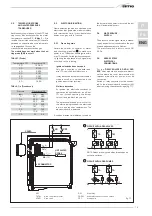

Gas connections must be made in accor-

dance with current standards and regula-

tions. When dimensioning gas pipes from

the meter to the module, both capacity

volume (consumption) in m

3

/h and gas

density must be taken into account.

System pipe sections must be able to gua-

rantee sufficient supply to cover maximum

demand, limiting pressure loss between the

meter and any utility device no greater than

1.0 mbar for second family gas (natural

gas). A sticker inside the module includes

identification and gas type data specific to

the module.

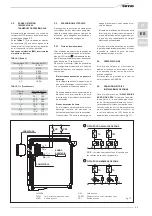

2.3.1

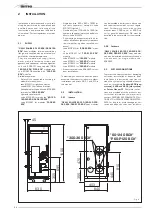

Condensation drain connection

A siphoned drain must be connected to

the civil drain by a pipe with minimum 5

mm per meter gradient for condensation

collection.

Only normal plastic civil drain pipes are

suitable to convey condensation to the

building’s sewer drain.

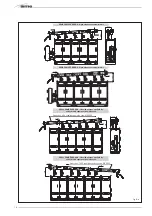

2.3.2

Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate to

entrap all the impurities in the gas or in gas

main pipes.

To prevent malfunctioning of the valve, or in

certain cases even to cut out the safety devi-

ce with which the valve is equipped, install an

adequate filter on the gas pipe.

2.5

FILLING THE SYSTEM

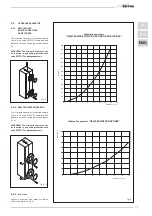

Cold system filling pressure must be

1 bar

. The

system must be filled slowly so that air bubbles

are released through the specific escapes.

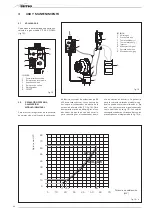

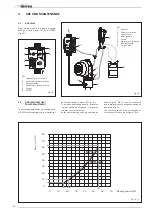

2.6

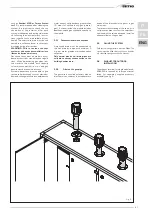

EXHAUST FOR OUTDOOR

INSTALLATION

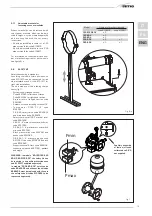

The exhaust terminal for single module cod.

8089530 is required for this type of instal-

lation. For separately supplied accessory

assembly see fig. 5.

Fig. 5

Summary of Contents for DEWY EQUIPE 120 BOX

Page 2: ......

Page 88: ......

Page 89: ...TAGLIARE LUNGO LA LINEA TRATTEGGIATA ...

Page 90: ......

Page 91: ......