12

with a slope of at least 5 mm per metre to

ensure drainage of condensation water.

The plastic pipes normally used for civil

drains are the only type of pipe which is

appropriate for conveying condensation

to the building’s sewer pipes.

2.4.6

Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate to

entrap all the impurities in the gas or in gas

main pipes. To prevent malfunctioning of the

valve, or in certain cases even to cut out the

safety device with which the valve is equip-

ped, install an adequate filter on the gas pipe.

2.4.7

Discharge Pipe

See fig. 6 for example discharge pipe termi-

nations.

2.5

FILLING AND COMMISSIONING

2.5.1 D.H.W.

circuit

Before filling the D.H.W. system, ensure

appliance selector knob is in the “Off” posi-

tion, then open the hot water tap nearest

the appliance. Open the D.H.W. supply isola-

ting valve to the appliance, once water

starts to flow from the tap close it, and then

open and close each hot water tap in turn

to ensure that all the air is removed from

the pipework. Open the hot water tap

furthest away from the appliance and let

water flow for about 10 minutes, or for suf-

ficient time to flush out the system. Check

for leaks.

2.5.2 C.H.

circuit

Once the D.H.W. circuit is commissioned

the C.H. circuit can be filled via the external

filling loop. Ensure both the D.H.W. and C.H.

temperature controls are set to minimum,

and that there is no room thermostat

demand. Turn on the electrical supply

to the appliance, (see Section 2.10), and

turn the selector knob to the summer posi-

tion. Open the filling loop’s C.H. isolating

valve and then the D.H.W. double check iso-

lating valve (See fig. 2 & 5/a).

Once the green

“1 bar”

led lights up close

both isolating valves, and disconnect the

flexible hose from the D.H.W. double check

isolating valve. Check for leaks and free

rotation of the circulating pumps. The

appliance can then be commissioned by fol-

lowing the User Instructions.

2.6

COAXIAL DUCT ø 60/100

The air inlet-smoke outlet assembly, code

8096250, is included in the standard sup-

ply of the appliance complete with mounting

instructions.

2.6.1

Coaxial duct accessories

The accessories to be used for this type of

installation and some of the connecting

systems that may be adopted are illustred

in fig. 7.

With the pipe bend included in the

kit, the maximum length of the piping

should not exceed 4.6 meter.

When the

vertical extension code 8086950 is used,

the terminal part of the pipe must always

come out horizontally.

2.6.2

Positioning the outlet terminals

The outlet terminals for forced-draught

appliances may be located in the external

perimeter walls of the building.

To provide some indications of possible solu-

tions,

Table 1

gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 8.

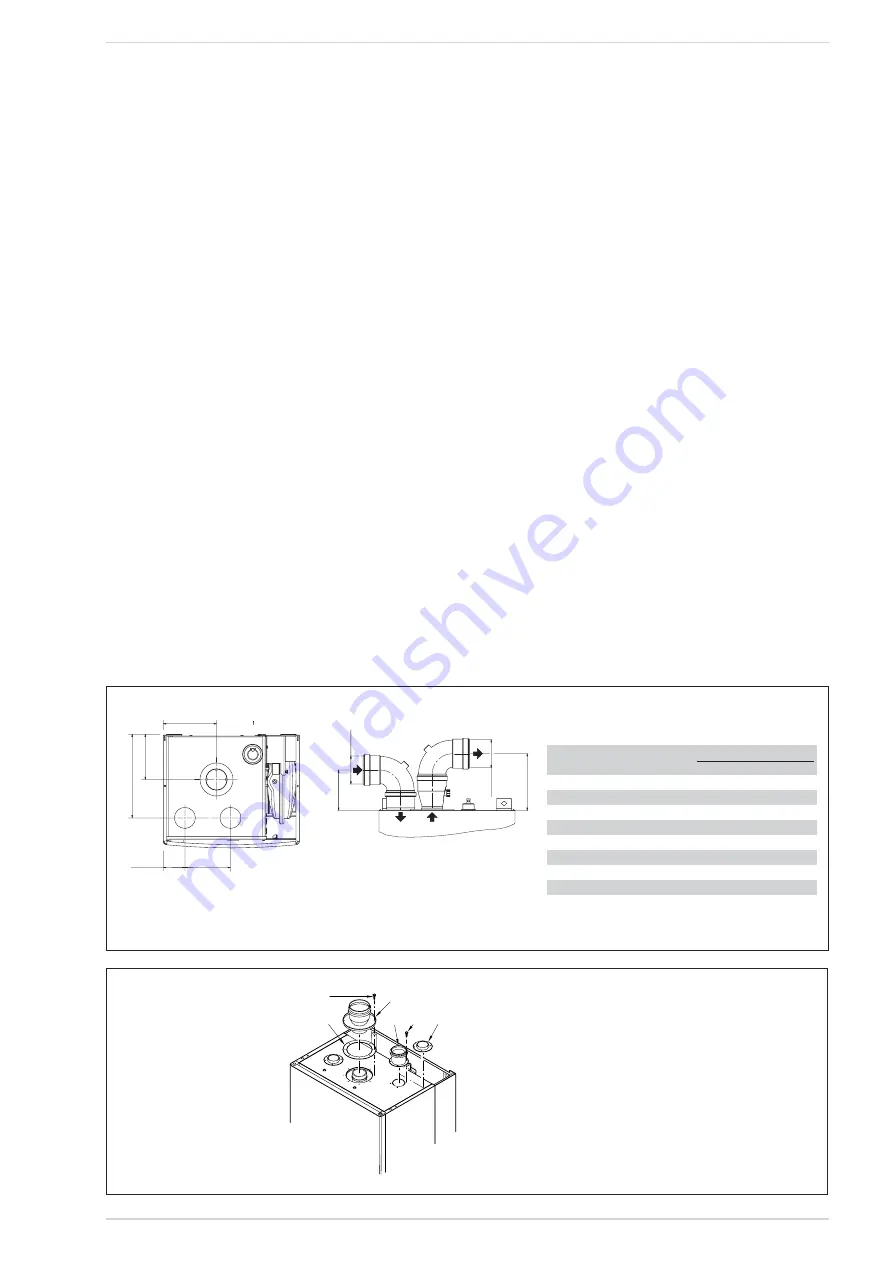

2.7

SEPARATE PIPES ø 80

A special kit may be used to separate the

flue gas outlet from the fresh air intake.

The intake may be installed to the right or

left of the flue gas outlet.

1

2

3

4

5

3

Fig. 10

KEY

1

Blind flange

2

Flue gas duct flange

3

Fixing screw

4

Gasket ø 125/95

5

Intake duct collar

Fig. 9

156,5

13

3

24

6

63,5

134

CS

CA

CA

11

8

Ø 80

Ø 80

16

6

KEY

CA

Inlet

CS

Outlet

TABLE 2

Accessories ø 80

Head loss (mm H

2

O)

Inlet

Outlet

Roof outlet

90° elbow MF

0.30

0.50

–

45° elbow MF

0.20

0.40

–

Extension L. 1000 (horizontal)

0.20

0.40

–

Extension L. 1000 (vertical)

0.30

0.30

–

Outlet terminal

–

0.40

–

Inlet terminal

0.10

–

–

Doubler fitting

0.30

–

–

Roof outlet terminal L. 1381

–

–

0.60