2686

7

GB

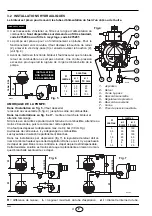

4.3 ELECTRODES SETTING

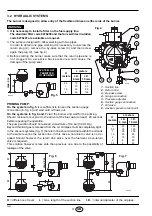

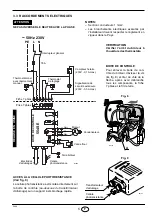

4.4 AIR DAMPER ADJUSTMENT,

(see fig. 12)

The mobile air damper (1) operated by the jack (2) assures the complete opening of the air intake.

The regulation of the air-rate is made by adjusting the fixed air damper (3), after loosing the screws (4). When

the optimal regulation is reached, screw tight the screws (4) to assure a free movement of the mobile air

damper (1).

The settings, indicated in the table (page 6), refer to the burner with its

cover fitted and combustion chamber with depression zero. These

regulations are purely indicative.

Each installation however, has its own unpredictable working condi-

tions: actual nozzle output; positive or negative pressure in the com-

bustion-chamber, the need of excess air, etc.

All these conditions may require a different air-damper setting.

It is important to take account of the fact that the air output of

the fan differs according to whether the burner has its cover

fitted or not. Therefore we recommended to proceed as follows:

➤

Adjust the air damper as indicated in the table.

➤

Mount the cover.

➤

Check smoke number and CO

2

.

➤

Should it become necessary to modify the air output, remove the

cover by loosening the screw, adjust the air damper, remount the

cover and finally recheck the smoke number.

4.5 PUMP PRESSURE:

The pump is set in factory according to the value indicated in the table B at page 6.

14 bar: Improves flame retention; it is therefore suitable for ignitions at low temperatures.

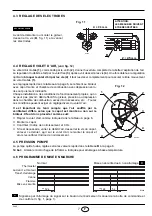

4.6 BURNER START-UP CYCLE

Lock out is indicated by a lamp on the control box (3, fig. 1, page 1).

Before removing or assembling the

nozzle, loosen the screw (B, fig. 11)

and move the electrodes ahead.

ATTENTION

Fig. 11

2

–

2.5

mm

4 ±

0.3 mm

IMPORTANT:

THESE DIMENSIONS

MUST BE OBSERVED

D5230

B

Fig. 12

4

3

D6286

4

1

2

Lock-out due to failure to light

C

Normal

D5029

~

12s

Thermostat

Green led and motor

Ignition transformer

Oil valve

Flame

Lock-out lamp

~

12s

5 s

C