MBA1000

Datum 26.08.2008

Art.Nr. 79828

Änd. Stand 318/08

11

5.3 Sensor's SSI-interface

MSA1000's SSI-interface allows a synchronuous out-

put of the position value. Its data format comprises

a width of 24 bit which are either issued as Gray or

binary codes (see chapter 7) and right-aligned. All

following bits (25, 26...) are issued as "0".

Data signals correspond to RS422. Cycle inputs are

opto-decoupled and also correspond to RS422. Ty-

pical SSI monoflop time is . 20...25µs which gives

a min. cycle rate of 62,5kHz.

Please note that the possible max. cycle rate and

data integrity mainly depend on the length of the

connection line. The following standard values can

be given:

line length 2m

max. cycle rate:

1 MHz

line length 10m

max. cycle rate:

800 kHz

line length 100m

max. cycle rate:

250 kHz

line length 200m

max. cycle rate:

125 kHz

5.4 Sensor in bus operation

Two different protocols are implemented in the

MSA1000 firmware.

The differentiation between the "service mode"

and the "SIKONETZ3" protocol is effected via the

wiring of the configuration input on "pin L" of the

connector.

After switching on, the RS485 interface is set to

"service mode" as long as the configuration input

"pin L" is not wired. The device address required

for subsequent bus operation (SIKONETZ 3) can

only be changed in this mode (default address

01). After switching on the sensor, the program-

ming tool "demo1000.exe" must be started and

the displayed sensor paraqmeters be checked. The

software version should be 1.01 or better. Using

function key "F5", the sensor address (01...31)

can be entered and shown in the window that

is dis-played. The address is then automatically

stored in the sensor and is retained after swit-

ching off the power supply.

The configuration input "pin L" must be put to

GND whenever the sensor is used during bus ope-

ration. The input is queried during startup, and in

this case the RS485 protocol is set to SIKONETZ3.

6. Trouble shooting

Below there are some typical errors which may oc-

cur during installation and operation:

Sensor not or incorrectly connected (for pin

connection see chapter 4).

Tolerance for the gap between magnetic sensor and

magnetic strip not observed over the total travel

•

•

distance. Sensor touches strip (see chapter 7).

Cable squeezed / interrupted / cut by sharp

edges.

Sensor’s active side not mounted towards the

magnetic strip (see fig. 8).

Sensor and magnetic strip have been incorrectly

aligned (see chapter 1).

Magnetic fields near the measuring surface distort

the measuring values. If required, pro-vide for

adequate screening.

Wrong measuring values due to EMC interferences

(see chapter 4).

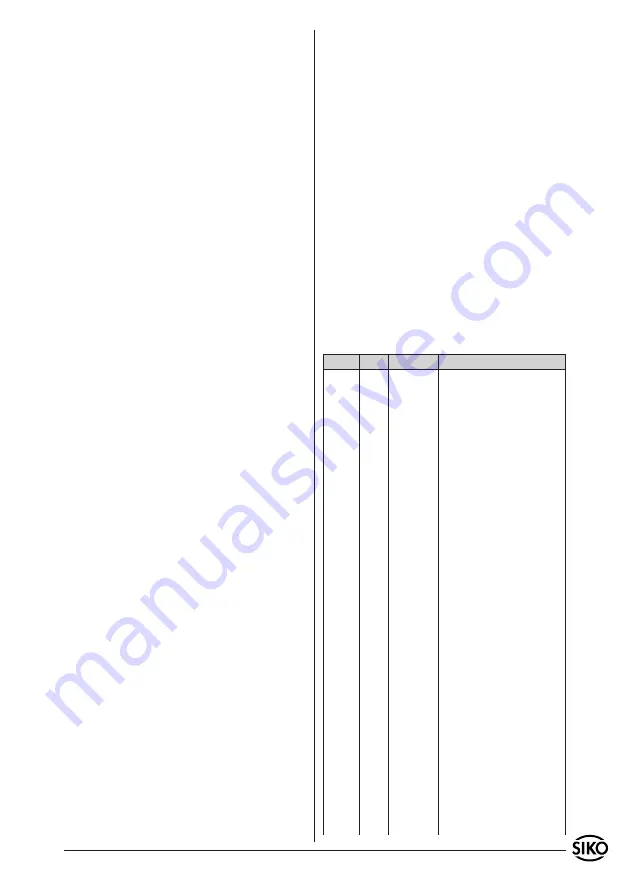

7. List of commands / service mode

Parameters: 19200 Baud, no parity, 8 bit, 1 stop

bit, no handshake

Data code: ASCII / Hexadecimal

Value range: 2/3 Byte: 0...65535 / 0...± 2

23

All replies which are confirmed by ">" end with

"CR" (Dez 13)."

Com.

Length Reply

Description

Ax

Send unit type/software version

2/9 "xxxxxxx>" x=0: hardware version

2/10 "xxxxxxxx>" x=1: software version

B

1/10 "±xxxxxxx>" Send absolute value (without cor-

rection values)

Ey

2/10 "±xxxxxxx>" Issue a 3-byte value

y=address (0...4)

y=1:position value

y=2:zero position value

y=3:calibration value

y=4:offset value

±xxxxxxx=dec. value

Fy±xxxxxx

9/2 ">"

Enter 3-Byte value

y=address (2...4)

y=2:zero position value (default=0)

y=3:calibration value (default=0)

y=4:offset value (default=0)

±xxxxxxx=dec. value

K

1/0 ""

Software reset

L

1/2 ">"

zero position value (calibration)

Nx

2/2 ">"

enter SSI output code

x=0: Gray code (default)

x=1: binary code

Qxx

3/2 ">"

enter device address (for SIKO-

NETZ 3 protocol)

xx= 01...31

R

1/4 "xx>"

output device address

xx= address

Sxxxxx

6/2 ">"

restore default programming

x= 11100 (s_befehl)

zero point/calibration/offset va-

lue =0

count. direct.= positive

output code= Gray

device address = 01

Tx

2/2 ">"

enter counting direction

x=0: positive count. direction (default)

x=1: negative count. dirction

•

•

•

•

•