MSK500/1

+MB500/1+MR500

Datum 12.05.2015

Art.Nr. 81413

Änd. Stand 87/15

11

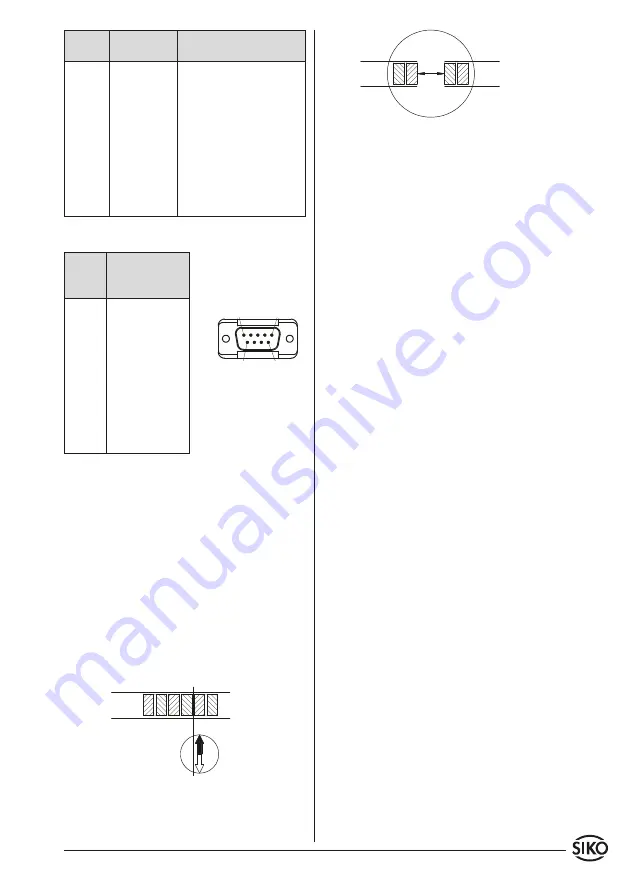

viewing side = plug-in side

plug pin

Fig. 10: Determination of the pole position. Cutting

the magnetic strip

Fig. 11: Determination of the pole position. Joining

the magnetic strip

Signal

inverted

inverted with

reference signal

A

Pin 1

Pin 1

B

2

2

I, R

- - -

3

+UB

4

4

GND

5

5

A/

6

6

B/

7

7

I/, R/

- - -

8

nc

3, 8, 9

9

E8E:

Connection with 9 pole D-SUB plug.

Signal inverted with

reference

signal

nc

PIN 1

I/, R/

2

B/

3

A

4

GND

5

+UB

6

I, R

7

B

8

A/

9

5. Joining magnetic strips together

For some applications it may be necessary to extend

the magnetic strip. The magnetic strip can be cut

and rejoined using standard tools.

But however carefully this is done the accuracy of

the strip at the join will be impaired (error of at

least 0.1 ... 0.2 mm).

The following tools / accessories are required:

• magnet magnifier, magnetic foil or metal dust

• rule or suitable tool

• compass needle

Steps

• If there is a cover strip, this is to be removed first.

• To determine the pole division either use metal

dust, a magnet magnifier or magnetic foil.

• If necessary, use a compass needle to determine the

location of the poles on the magnetic strip (fig. 10).

• Use a rule and a sharp knife to cut the magnetic

strip at a right angle. Then also cut the carrier

strip accordingly.

• Previous steps are to be repeated with the other

part of strip.

• Check polarity before joining the two parts.

Both ends must attract each other (if necessary,

use compass needle). In case both ends have the

same polarity, shorten one end by a half pole

division (fig. 11).

• Join the two ends closely together and add the

cover strip.

6. Maintenance

We recommend cleaning the magnetic strip's sur-

face from time to time with a soft rag. This avoids

dirt (dust, chips, humidity ...) sticking to the strip.

7. Trouble shooting

Below are some typical errors which may occur duri-

ng installation and operation:

• Magnetic strip incorrectly mounted (active sur-

face must be mounted towards the sensor) (see

chapter 3.1).

• Use of foreign protective strip. Must always be

non-magnetic.

• Sensor not or incorrectly connected (pin connec-

tion, see chapter 4.2).

• Tolerance for the gap between magnetic sensor

and magnetic strip not observed over the

total

travel distance. Sensor touches strip (see fig. 6+7).

• Cable squeezed / interrupted / cut by sharp edges.

• Sensor's active side not mounted towards the

magnetic strip (see fig. 6+7).

• Sensor has not been aligned according to fig. 6+7.